Design and Electrical Control of Fully Automatic Carton Packaging Machine

With the development of the commodity economy, the market's demand for packaging applications has gradually changed. Compared to other packaging methods, carton packaging can adapt to the packaging needs of various types of products and offers significant flexibility advantages. However, many manufacturing companies face the issue of insufficient carton packaging production capacity, making it difficult to meet the demands of large-scale and rapid product packaging needs. To address this, a fully automatic high-speed carton packaging machine can be employed, which can enhance overall production efficiency and meet diverse packaging requirements. To ensure the smooth application of the packaging machine, proper design and electrical control work are necessary. This article delves into this topic.

Keywords: Fully Automatic Carton Packaging Machine; Design Discussion; Electrical Control

Introduction:

Carton packaging serves numerous purposes, offering protection to products. The stacking capability of cartons meets the requirements for extensive storage and transportation. Additionally, the information and decorative elements on carton surfaces showcase product types and contribute to sales. Moreover, carton packaging boasts low costs, further enhancing its advantages. Hence, carton packaging finds extensive applications. To address diverse product packaging needs, specific standards must be met, including carton dimensions, thickness, fold endurance, puncture resistance, edge crush strength, adhesive strength, compression strength, moisture content, moisture resistance, layer quantification, flat crush strength, etc. Adopting a fully automatic high-speed carton packaging machine ensures packaging compliance with these standards. Thus, the selection of packaging machinery, along with design and electrical control considerations, is crucial.

Current Development Status of Carton Packaging

Among various packaging forms, shrink packaging is widely used due to its economic, safety, and convenience characteristics. However, this packaging form has limitations and cannot meet the demands of long-distance transportation for cross-regional sales. Therefore, combining more stable and suitable carton packaging with shrink packaging can enhance overall packaging performance. Moreover, due to labor-intensive packaging processes, significant labor force is required, leading to increased operational costs. Integration of automation technology can help reduce costs. Currently, China's carton packaging capacity needs development, as many carton packaging machines operate at low efficiency, only satisfying small-scale production packaging needs. To enhance comprehensive output capacity, optimizing the packaging process is essential. Employing a fully automatic high-speed carton packaging machine can improve efficiency. This requires studying carton packaging machine design and application experiences from domestic and international sources.

Basic Composition and Principles of Fully Automatic Carton Packaging Machine

Basic Composition:

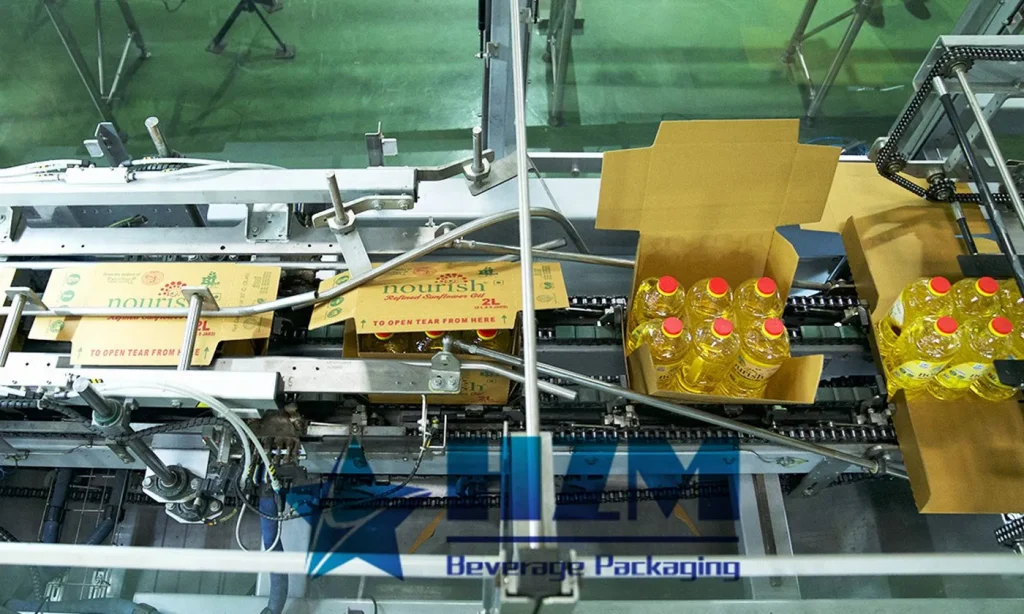

The system configuration of the packaging machine centers around two working elements: paper products and cartons, as well as packaged bottles. The operation of the packaging machine involves tasks such as supplying carton boards, retrieving paperboards, and conveying. It also includes folding cartons into shape and performing glue spraying and sealing after folding. Continuous supply of carton board is necessary to ensure efficient supply.

In handling packaged bottles, tasks include bottle conveyance, bottle separation, and bottle pushing. Mechanically driven transportation and newspaper delivery enable packaged bottles to enter cartons. Each task has corresponding equipment. Two crucial functions during packaging machine operation involve controlling motor speed and package conveyance. Motor speed control can be achieved through frequency conversion, adjusting speed based on the packaged product quantity and carton packaging requirements. Conveyance rhythm control is also vital for stable pacing.

Application Principles:

The packaging machine operates with high efficiency, enabling full automation. Material retrieval involves servo motor operation driven by the main and auxiliary drives, similarly applied to bottle transportation. To retrieve materials, two sets of disc mechanisms alternate, ensuring uninterrupted carton board supply. In bottle separation, systematic grouping is essential to ensure the supply rhythm of packaged bottles matches carton board supply. The bottle pushing structure strengthens the packaging bottle's tightness within the carton, preventing excessive gaps that could hinder packaging efficiency. Additionally, carton material and packaging need processing.

The packaging machine completes material processing and packaging. Sealing is the final step, requiring precise adhesive spraying based on material condition, carton structure, and product weight.

Design Scheme of Automatic Carton Packaging Machine

The design of the packaging machine requires overall consideration of packaging application demands. Design elements encompass control system design, operational position detection device design, and packaging cycle design. Control system design involves using motion controllers to control various devices, including servo motors, drivers, detection devices, and execution devices. Overall control requires connecting servo drives via a bus to control motors. Servo motor drive includes a main motor and a secondary motor. Collaborative operation ensures safety and stability. The packaging machine has detection functions, displaying accurate position information based on related data, achieving position monitoring. Moreover, packaging cycle design is essential during packaging.

As the bottle-pushing rod moves, each group of bottles requires one carton for packaging. Switches around the bottle-pushing rod detect related operational data, using periodic position data for cycle design and rational adjustment, achieving effective operational control.

Control Principles and Electrical Control of Automatic Carton Packaging Machine

Control Principles:

In packaging machine operation, two main controls are required: bottle separation motor control and paperboard system control. Firstly, bottle separation requires two motors to alternate, maintaining stable alternating speeds. Specifically, when one motor reaches its limit position, the other starts moving, ensuring stable alternating motion. This control can be achieved through two proximity switches—one for detecting the active shaft's position and the other for the passive shaft's position.

Secondly, the paperboard system has two supply modes: vertical and horizontal. Thus, two motors are required for cooperation. Vertical supply utilizes one motor, while horizontal supply uses another. Collaboration between these two motors ensures normal paperboard system operation.

Electrical Control:

In bottle separation control, the bottle separation motor alternately stops in a regular pattern. Pulse synchronization between driving motors is achieved, and the passive motor maintains collaborative motion. Specifically, when the active shaft motor reaches its limit position, a signal is sent by the proximity switch, triggering a PLC program to synchronize the pulse of the passive shaft motor with the active shaft motor's pulse. Simultaneously, the passive motor maintains collaborative motion, ensuring proper bottle separation function.

Human-machine interface (HMI) plays a crucial role. HMI provides an interactive interface between operators and the machine, allowing operators to easily set machine operation parameters and view operational status. In the packaging machine, HMI connects via PLC programs. Operators can set bottle separation motor operation parameters, such as pulse count and speed, through the HMI. Additionally, the HMI displays the packaging machine's status, including operational status and fault information.

TAG: Carton Packing Machine Packaging machine

-

![Raw Water Treatment System for Beverage Plant]()

Raw Water Treatment System for Beverage Plant

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line