Automatic Pure Water Bottling Filling Machine for PET bottle integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, drinking water etc.

Automatic Pure Water Bottling Filling Machine

Function : Washing, Filling, Capping

Bottle : PET Bottle

Volume : 500ML~10L.

Capacity : 5,000~18,000BPH.

Applicable : Mineral water, Pure Water, still drinks.

Price : Click the button below to obtain the price.

Other : Customizable according to needs.

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Parameters

| Model | Capacity | Bottle Size | Air Pressure | Voltage | Power | Dimensions |

|---|---|---|---|---|---|---|

| XGF14-12-5 | 5,000 bph | 50-110 mm | 0.7 MPa | 380/415 V | 1.5 kW | 2360x1770x2700 mm |

| XGF16-16-5 | 8,000 bph | 50-110 mm | 0.7 MPa | 380/415 V | 2.2 kW | 2760x2060x2700 mm |

| XGF24-24-8 | 12,000 bph | 50-110 mm | 0.7 MPa | 380/415 V | 3.0 kW | 2800x2230x2700 mm |

| XGF32-32-8 | 15,000 bph | 50-110 mm | 0.7 MPa | 380/415 V | 4.0 kW | 3550x2650x2700 mm |

| XGF40-40-10 | 18,000 bph | 50-110 mm | 0.7 MPa | 380/415 V | 7.5 kW | 4360x3300x2700 mm |

Features

1. This water filling machine has a compact structure, perfect control system, easy to operate and highly automated.

2. Only by changing the star-wheel, arch board can realize fill bottle shape change.

3. The parts contact with product is made of quality SUS316/304, anti-corrosive, and easy to clean.

4. Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

5. The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

6. This water filling machine has a high efficient cap arranging system, perfect cap feeding with self-control and self-protection device.

7. The water filling machine adopts perfect overload protective device can ensure the operator and machine safety.

8. The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

9. The main electric and air-drive components are world famous brand products.

10. All control is advanced touch-screen operation and realize people-computer dialogue operation.

part

Rinsing Part

1. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

2. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, saving rinsing water.

3. Covering of bottle clamps and elevator are product of Igus.

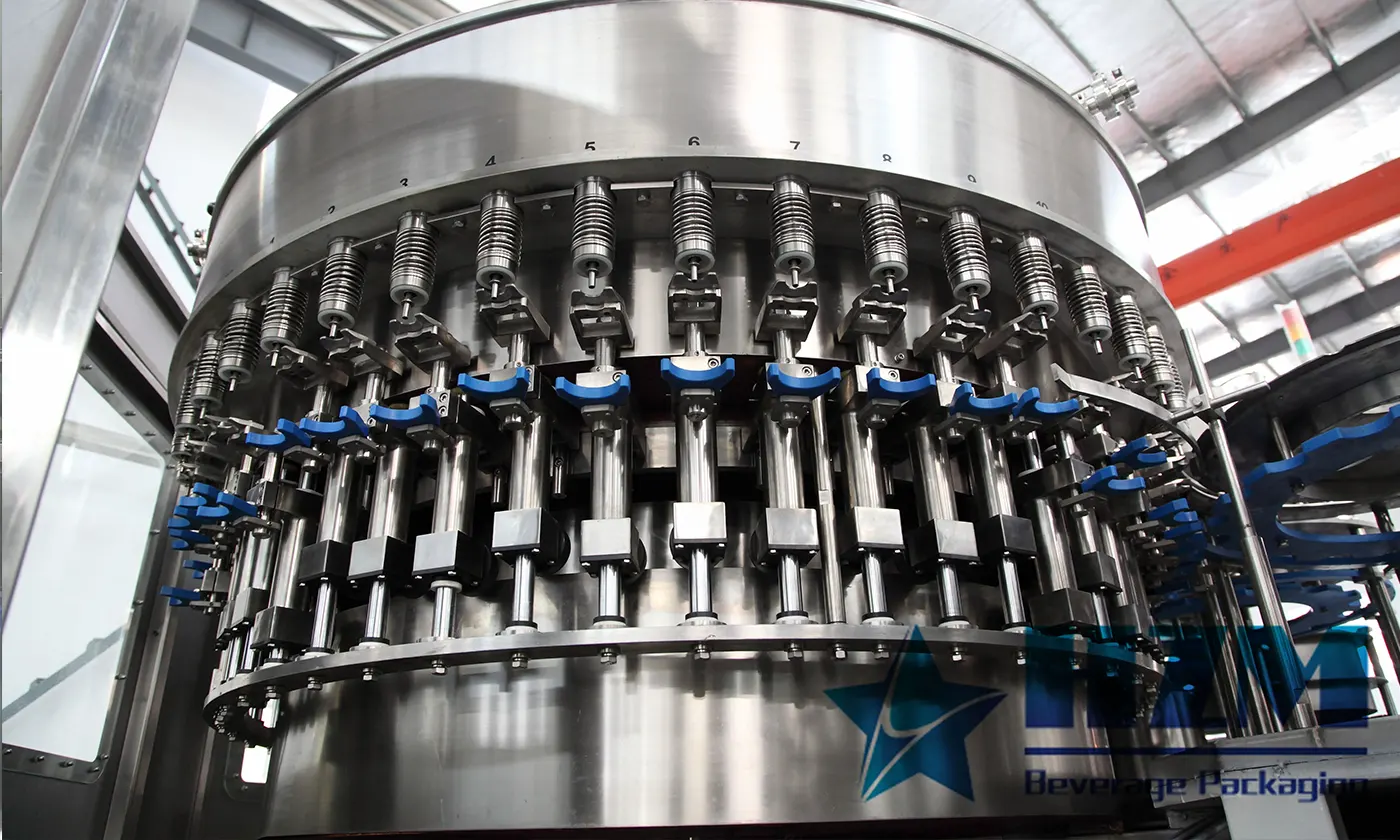

Filling Part

1. Filling valves are designed and manufactured with German technology, featuring high filling accuracy and high filling speed.

2. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

3. Filling valves are made of SUS316.

4. Hydraulic pump is float-ball controlled.

Capping Part

1. Highly effective acentric way for cap sorting to reduce the abrasion.

2. The fall guide rail has the device to prevent the reversal cap from passing and pick out the reversal cap.

3. It has the bottle check-up switch to control the cap flow and stop it in case no bottle to reduce the cap quantity.

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine