Core parameters

| Attribute |

Details |

| Packaging Type |

Bottles |

| Warranty |

2 years |

| Driven Type |

Mechanical |

| Voltage |

Customized |

| Automatic Grade |

Automatic |

| Packaging Material |

Plastic, Glass |

| Application |

Beverage |

| Filling Material |

Juice |

| Filling Accuracy |

99.5% |

| Machinery Capacity |

4000BPH, 6000BPH, 8000BPH, 12000BPH, 16000BPH, 18000BPH, 20000BPH, 21000BPH, 28000BPH, Other |

| Place of Origin |

Jiangsu, China |

| Brand Name |

HZM |

| Dimension (L×W×H) |

According to model |

| Key Selling Points |

High Productivity |

| Machinery Test Report |

Provided |

| Video Outgoing-Inspection |

Provided |

| Core Components |

Motor, Pump, PLC, Gear, Bearing, Engine |

| Application Scope |

Juice Beverage / Tea Beverage / Liquor |

| Filling Capacity |

4,000BPH – 28,000BPH |

| Filling Volume |

200ml – 2000ml |

| Suitable For |

PET Bottle / Glass Bottle |

| Material |

SUS304 / SUS316 |

| After-Sales Service Provided |

Free spare parts, Field installation, commission and training |

Detail display of filling line

Rinsing Part

1. The sealing ring is made of EPDM material, and plastic is made of UMPE.

2. The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water.

3. There is a cover above the spray nozzle which can prevent water spilling; and there are regulatory recycle slot and recycle pipes under the nozzles.

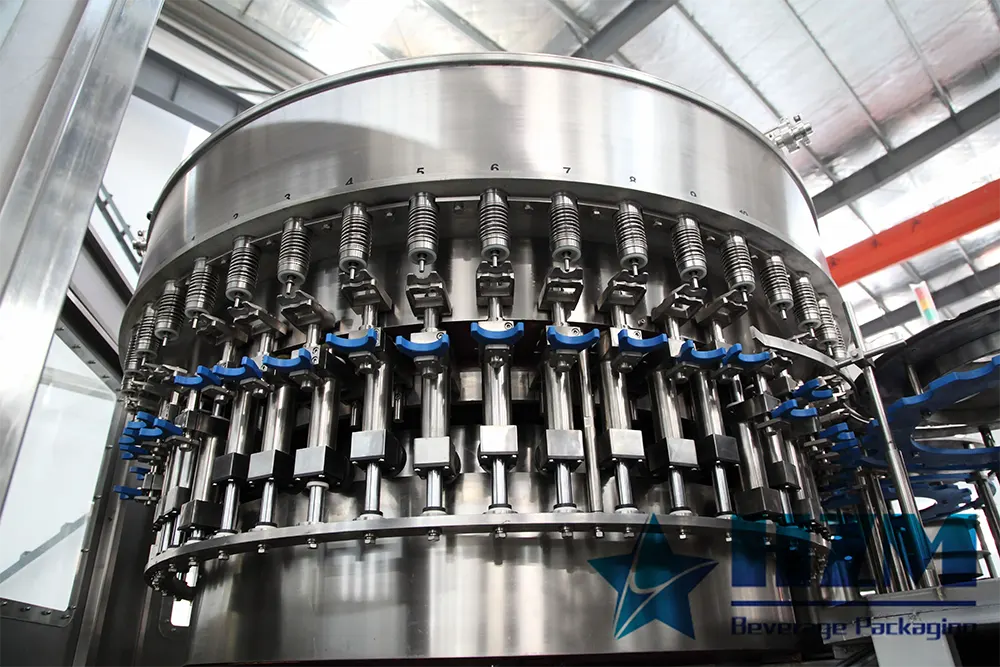

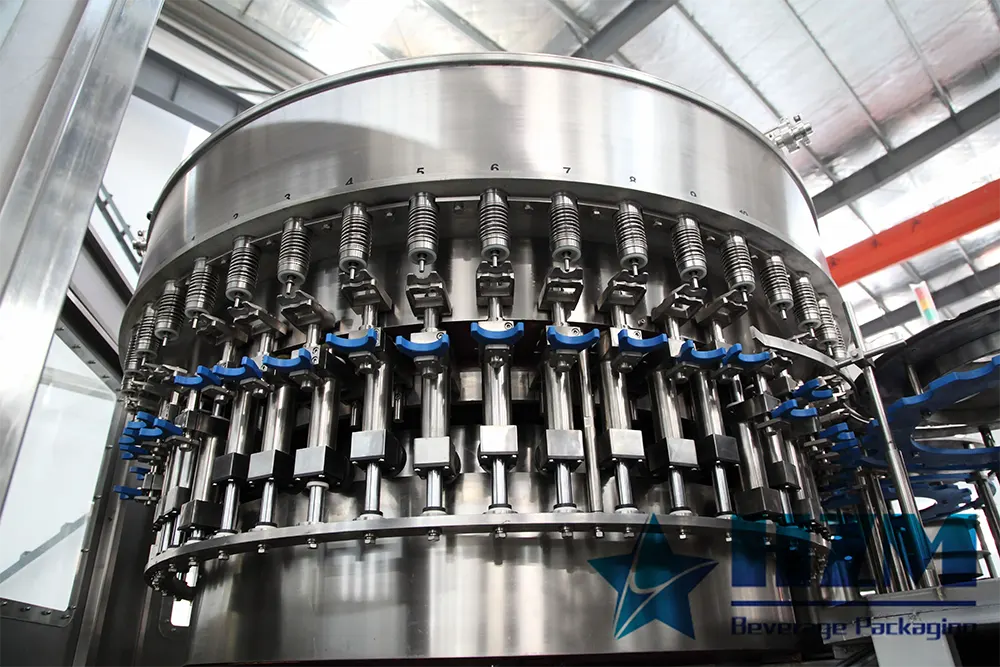

Filling Part

1. The filling system has CIP circulation system to wash the pipeline and fake-cup used for cleaning filling valve.

2. The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control.

3. This filling system has an automatic temperature control system.

Capping Part

1. The screwing capping head is dual-purpose design; it is suitable for flat cap and sport cap.

2. There are aseptic nozzles between the transition poking wheel and filling parts to rinse the product rested in the bottleneck screw parts.

3. There is a cap-lock cylinder in the joint between the cap-falling guide and cap distributor.

PRODUCT FEATURES

- 1. The filling machine adopts full filling method to avoid the bottle distorted after cooling and reduces dissolved oxygen at the maximum degree.

- 2. The product storage hopper and feed system of beverage filling machine adopt reasonable product feed design (constant flow, constant pressure, no foaming). Usually, the high-level tank is used for feeding product.

- 3. Product hopper with reasonable structure( exhaust, fully close, temperature can be detected). Medium and high speed line adopts product distributor instead of large liquid carousel, which can be cleaned completely by pressure cleaning with CIP.

- 4. The sanitary filling valve system with umbrella-flow type structure of beverage filling machine ensure the high speed.

- 5. The filling machine is equiped with perfect hot filling temperature control system.

- 6. The filling machine has the structure of product recycle tank system with automatic product feed start-up.

- 7. Perfect CIP system is used for the juice beverage filling machine to make sure the product hygiene and safety.

FAQ

Q1: What type of beverage can this machine fill?

A1: It is suitable for bottled water, flavored juice, carbonated drinks, energy drinks, and beer.

Q2: Can it handle different bottle sizes?

A2: Yes, the machine supports quick changeover between various bottle sizes and shapes.

Q3: Do you offer overseas installation and training?

A3: Yes, we provide on-site installation and operator training for international customers.

Q4: Is the machine customizable?

A4: Absolutely. Capacity, bottle type, labeling style, and other configurations can be tailored to your needs.

Q5: How long is the delivery time?

A5: Usually 30–60 working days depending on the specific requirements and machine complexity.