Core parameters

|

Outout for 500ml

|

12000-48000BPH |

| Rate of finished products |

99.5% |

| Mold cavities |

6-24N |

| Filling heads |

24-80 |

| Capping heads |

8-22

|

| Max bottle diameter |

110m |

| Max bottle height |

340 |

| Max bottle mouth diameter |

38mm |

| Max preform height |

135mm |

| Max volume |

2000ml |

| Medium power absorbed |

60% |

Overview – All-in-One Solution for PET Bottle Production

Our integrated PET bottle blowing filling capping machine (BFC combi-block) automates the entire process from preform to finished capped bottles, designed for high efficiency, precision, and sustainability. Ideal for water, carbonated drinks, juices, edible oil, and personal care products, this all-in-one line reduces labor costs, minimizes material waste. Whether you’re a startup or a large-scale manufacturer, our customizable BFC machines deliver reliable performance with flexible production capacities (12000–36000 BPH).

-

-

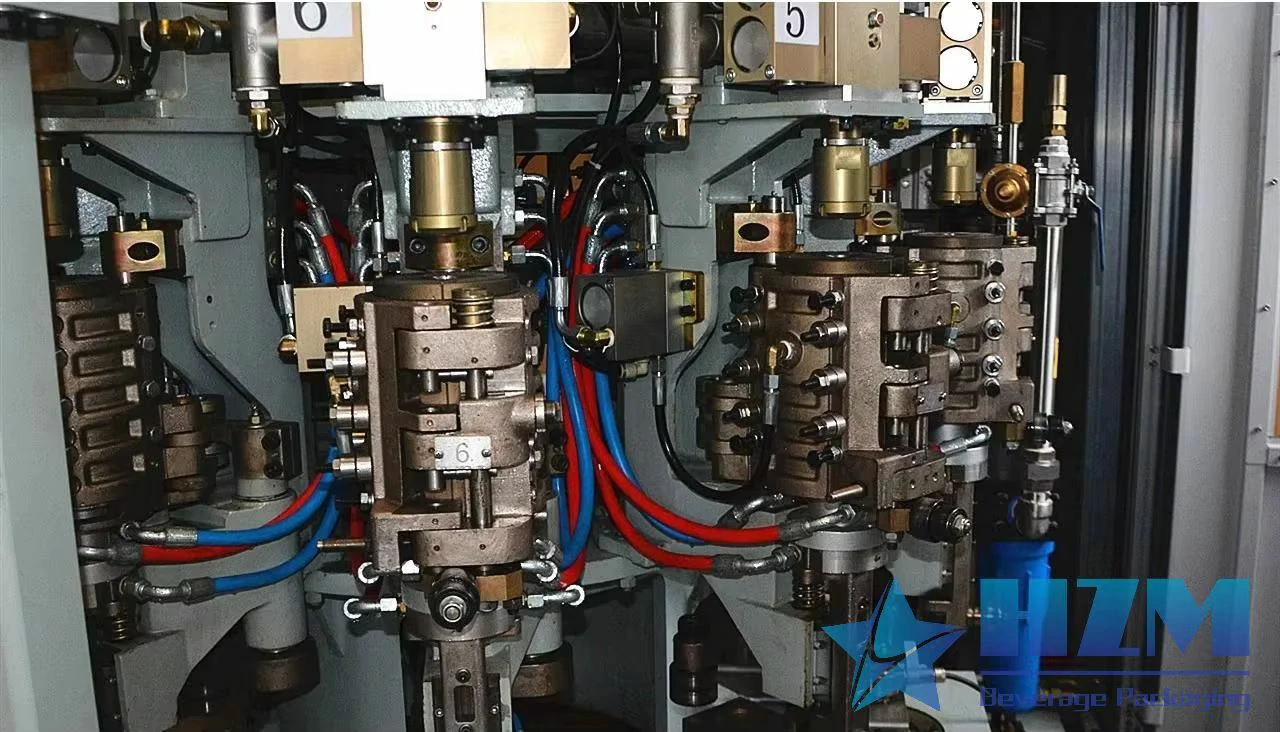

Equipment detail diagram

-

-

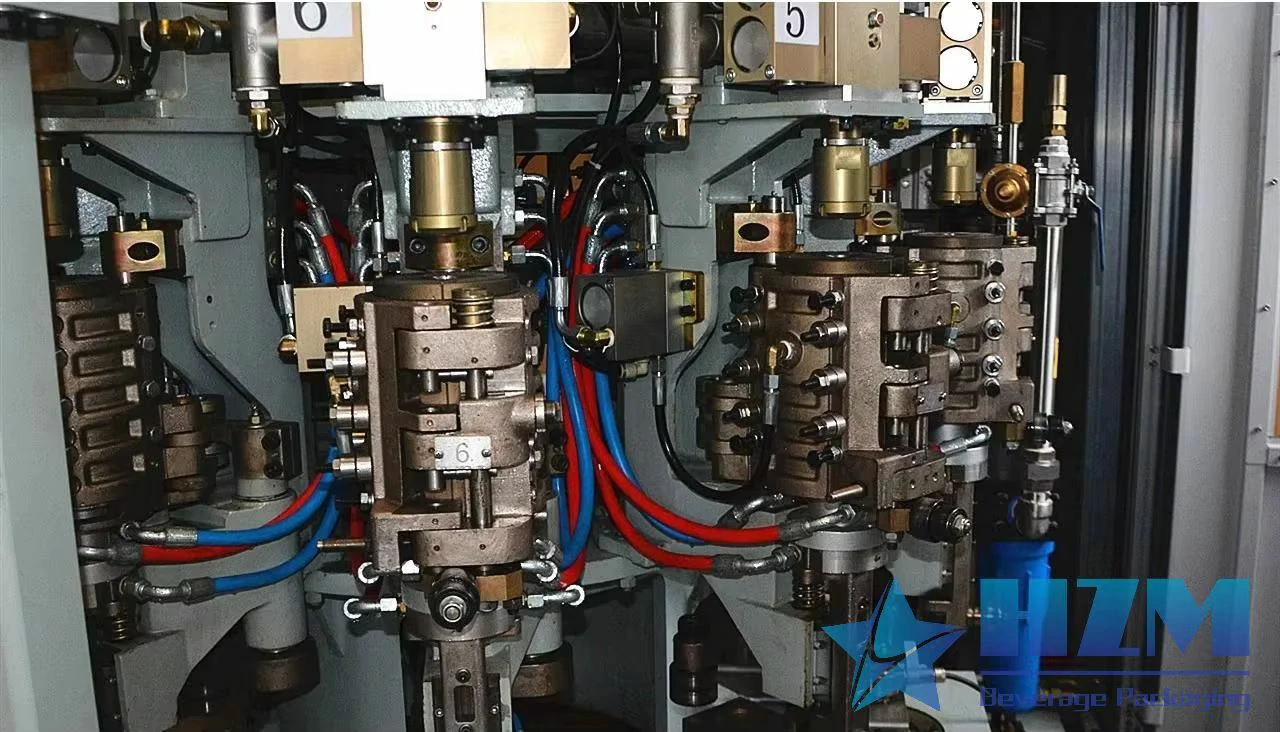

Equipment detail diagram

-

-

Equipment detail diagram

Product Advantages

Advantage-1

◇ The embryo inserting system has multiple safety protection devices to ensure the embryo inserting.

◇ Use continuous embryo implantation system.

◇ The device for conveying the preform to the heating extension blowing molding adopts a linear structure.

Advantage-2

◇ All-electric linkage structure ensures high-speed operation and precise positioning of the machine.

◇ Modular design, easy maintenance.

◇Save cost and increase competitiveness.

Advantage-3

◇ Improve energy efficiency.

◇ Human-machine interface control, simple operation.

◇ Equipped with gas recovery device.

◇ Low energy consumption, low maintenance, low wear, low pollution.

Applications – Industries We Serve

Our PET bottle blowing filling capping machines are widely used in:

Beverage Industry: Mineral water, carbonated drinks (soda), fruit juice, tea, energy drinks.

Food Industry: Edible oil, vinegar, soy sauce, liquid seasoning.

Personal Care & Household: Shampoo, detergent, hand sanitizer, disinfectant.

Pharmaceuticals: Oral liquids, medical disinfectants (aseptic model available).

Choose Us

We are a comprehensive professional supplier of liquid beverage packaging machinery, which integrates development, manufacture and sales. It has successively introduced several modern CNC processing equipment from the United States, Japan and other countries and regions. At present, it has about 50 million fixed assets.We can supply Turn-key project and have professional engineers for after-sales service.At present, the equipment is exported to domestic and overseas markets more than 30 regions and countries. Welcome more friends come to negotiate and consult.