Our Drinking Water Production Line – Bottled Water Filling Machine is specially designed for mineral water, purified water, and spring water bottling plants. From water treatment, rinsing, filling, to capping and packaging, the complete solution ensures safe, hygienic, and efficient production.

Whether you are running a small-scale bottling factory or a large commercial water plant, our equipment guarantees stable performance, low energy consumption, and high productivity.

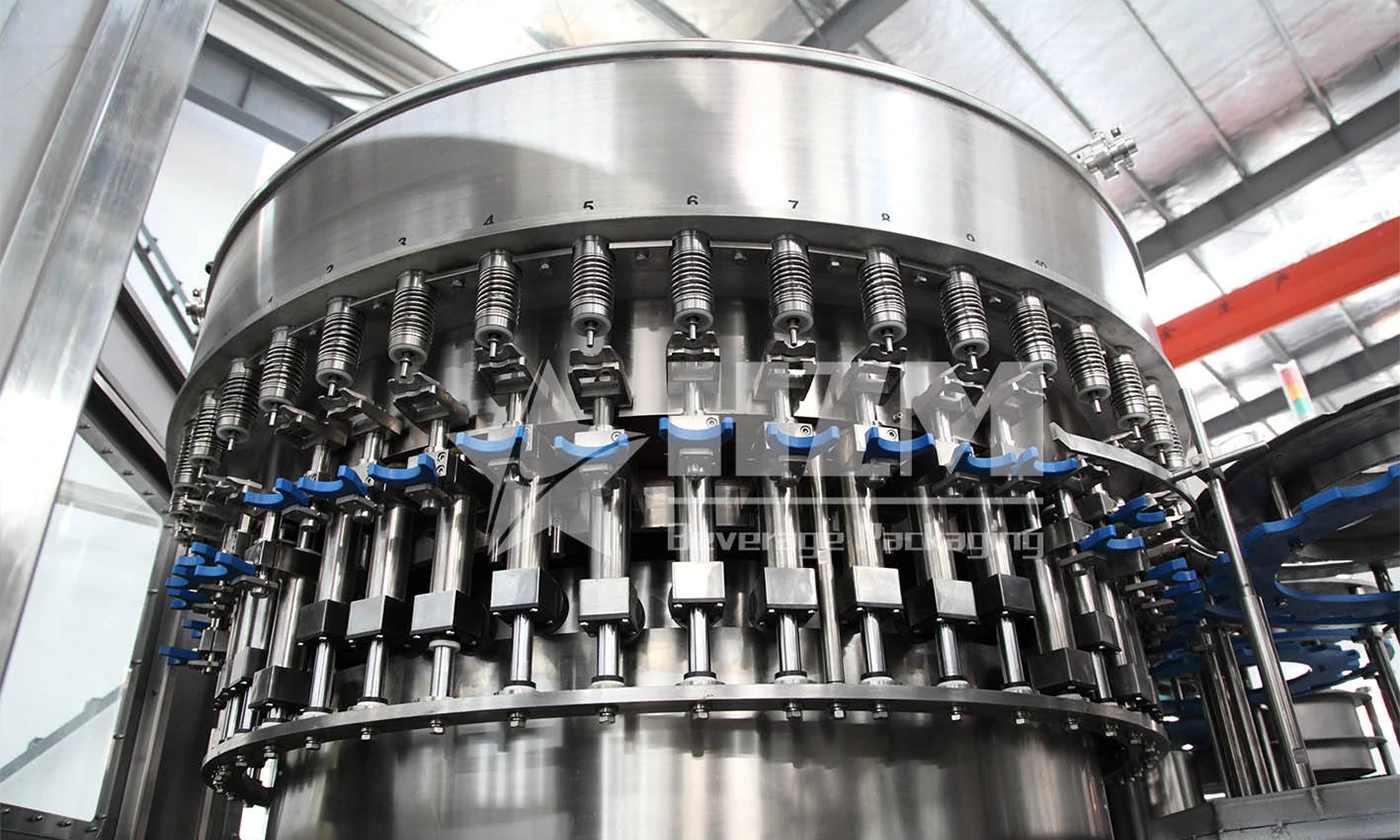

Drinking water production line – Bottled Water Filling Machine Manufacturer

Application: Suitable for water, juice, milk, beer, and other beverages.

Bottle Sizes: Handles small to large bottles with quick adjustment.

Production Capacity : 5000~18000BPH

Full Automation: Washing, filling, and capping integrated in one machine.

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Product Parameters

| Parameter | Details |

|---|---|

| Packaging Type | Bottles |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Warranty | 2 Years |

| Driven Type | Electric |

| After-sales Service | Video technical support, Online support, Free spare parts |

| Voltage | 380V, 50HZ |

| Automatic Grade | Automatic |

| Packaging Material | Plastic, Paper, Metal, Glass |

| Application | Food, Beverage, Water |

| Filling Material | Beer, Milk, Water, Juice, Other |

| Key Selling Points | Large Bottle Water Filling |

| Core Components | Motor, Pump, PLC |

| Filling Accuracy | 99.5% |

| Weight (KG) | 2000 |

| Place of Origin | Jiangsu, China |

| Brand Name | HZM |

| Dimension (L*W*H) | 2360*1700*2700 |

| Product Name | 3 In 1 Washing Filling Capping Machine |

| Feature | High Precision Filling Level |

| Material | SUS304/316 |

| Bottle Type | Plastic Bottle / Glass Bottle |

| Keywords | Small Bottle Filling Machine |

| Control | PLC (SIEMENS) |

| Motor | ABB |

| Model | XGF14-12-5, XGF16-16-5, XGF24-24-8, XGF32-32-8, XGF40-40-10 |

| Capacity (for 500ml) | 5,000BPH, 8,000BPH, 12,000BPH, 15,000BPH, 18,000BPH |

| Bottle Diameter | 50~110mm |

| Bottle Height | 160~310mm |

| Air Source Pressure | 0.7MPa |

| Voltage | 380/415V |

| Main Motor Power | 2KW, 2.2KW, 3.0KW, 4.0KW, 7.5KW |

| Dimension | 2360*1770*2700, 2760*2060*2700, 2800*2230*2700, 3550*2650*2700, 4360*3300*2700 |

Core Equipment

Full automatic water filling machine for PET bottle integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, drinking water etc.

- 1. This water filling machine has a compact structure, perfect control system, easy to operate and highly automated.

- 2. Only by changing the star-wheel, arch board can realize fill bottle shape change.

- 3. The parts contact with product is made of quality SUS316/304, anti-corrosive, and easy to clean.

- 4. Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

- 5. The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

- 6. This water filling machine has a high efficient cap arranging system, perfect cap feeding with self-control and self-protection device.

- 7. The water filling machine adopts perfect overload protective device can ensure the operator and machine safety.

- 8. The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

- 9. The main electric and air-drive components are world famous brand products.

- 10. All control is advanced touch-screen operation and realize people-computer operation.

Complete Bottled Water Production Line Solution

Why Choose Us?

-

Manufacturer Advantage – Direct factory supply, competitive price, and complete after-sales service.

-

Global Service – Exported to more than 50 countries worldwide, trusted by beverage brands.

-

Customization – Tailored solutions based on your bottle design, production capacity, and budget.

-

One-Stop Solution – From water treatment, filling machine to packaging line, all in one package.

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine

-

![Drinking water production line – Bottled Water Filling Machine Manufacturer]()

Drinking water production line – Bottled Water Filling Machine Manufacturer