This automatic oil filling machine is designed for high-precision filling of viscous liquids such as edible oil, sauce, honey, jam, and chemical liquids. It is equipped with a servo-driven piston system, diving nozzles, and a smart PLC control panel, making it ideal for PET bottles, glass bottles, barrels, and cans. Built for flexibility and efficiency, this machine supports multiple filling volumes from 500ml to 20L and output speeds up to 50 bottles per minute. It features 2–20 filling nozzles, depending on the model, and ensures filling accuracy up to ±1.0%.

Automatic Servo Piston Filling Line for Viscous Sauces – Ketchup, Soy Sauce, Mayonnaise

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Product Configurations

| Parameter | Value |

| Packaging Type | CANS, Bottles, Barrel, Glass Bottles |

| Warranty | 1 Year |

| Driven Type | Electric |

| Voltage | 380 V, 50/60 Hz |

| Automatic Grade | Automatic |

| Packaging Material | Plastic, Metal, Glass |

| Application | Commodity, Chemical, Oil |

| Filling Material | Water, Oil, Sauce |

| Filling Accuracy | ±5g |

| Machinery Capacity | 100BPH, 200BPH, 400BPH, 500BPH, 1000BPH, 2000BPH |

| Place of Origin | Jiangsu, China |

| Brand Name | HZM |

| Dimensions (L×W×H) | 3800 × 1450 × 1880 mm |

| Key Selling Points | Easy to Operate |

| Machinery Test Report | Provided |

| Video Outgoing-Inspection | Provided |

| Core Components | Motor, Pump, PLC |

| Application Description | PET Bottle Linear Type Oil Filling Machine |

| Product Name | Automatic Oil PET Bottle Filling Machine |

| After Warranty Service | 2 Years |

| After-Sales Service Provided | Engineer Support and Online Service |

| Production Capacity | 500–3000 BPH |

| Bottle Types | PET Bottle, Glass Bottle, Cans |

| Advantage | High Efficiency |

| Processing Types | Automatic Oil Piston Filling Machine |

| Filling Nozzles | 2–16 Filling Heads |

| Filling Products | Cooking Oil, Sunflower Oil, Sesame Oil |

|

Automatic Linear Piston Pressured Type Liquid Filling Machine |

|||||

| Model | HZM-6H | HZM-8H | HZM-12H | HZM-16H | HZM-20H |

| Filling nozzle | 6 | 8 | 12 | 16 | 20 |

| Dimension | 2000*1300*2350 | 2000*1300*2350 | 2800*1300*2350 | 2800*1300*2350 | 2800*1300*2350 |

| Power supply | 220/380V 50/60HZ, 2KW | ||||

| Filling speed |

20-50 bottles/minute |

||||

| Filling volume | 500-5000ml, 1L-10L, 2L-20L | ||||

| Filling form | Piston filling | ||||

| Filling accuracy | ±1.0% | ||||

| Air pressure | 0.6-0.8MPa | ||||

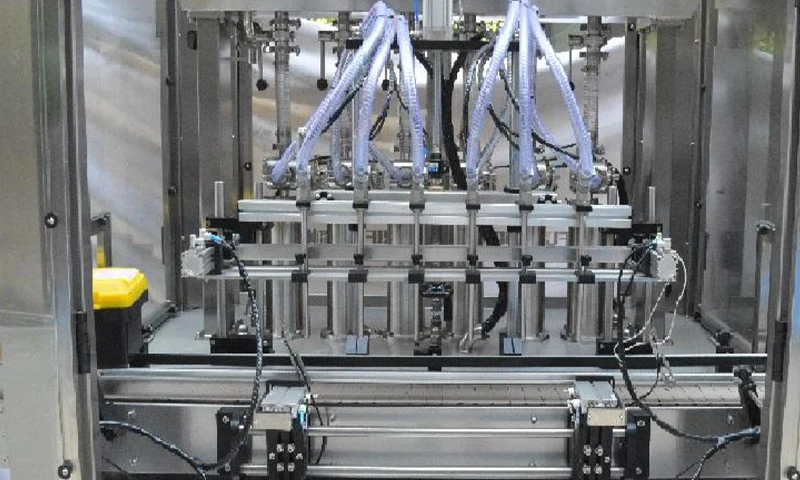

PRODUCT FEATURES

Diving nozzle

It is suitable for filling vegetable oil, honey, jam, syrup, preparation, suspension agent, oil and various viscous materials in

daily chemical industry. Equipped with pneumatic diving nozzle,it has larger power to fill liquid.The diving nozzle can prevent the liquid from splashing

as little as possible,improve filling accuracy.

It has high degree of automation and convenient adjustment. When changing specifications or revising measurement, it only needs to be adjusted on the display screen to meet the requirements.

Quantitative filling, adjustment for one key.Fast interface easy to be dismantled easy to wash, no drip,diving filling.The

internal adjustment of the machine is simple.Short adjustment time for replacing bottle shape.

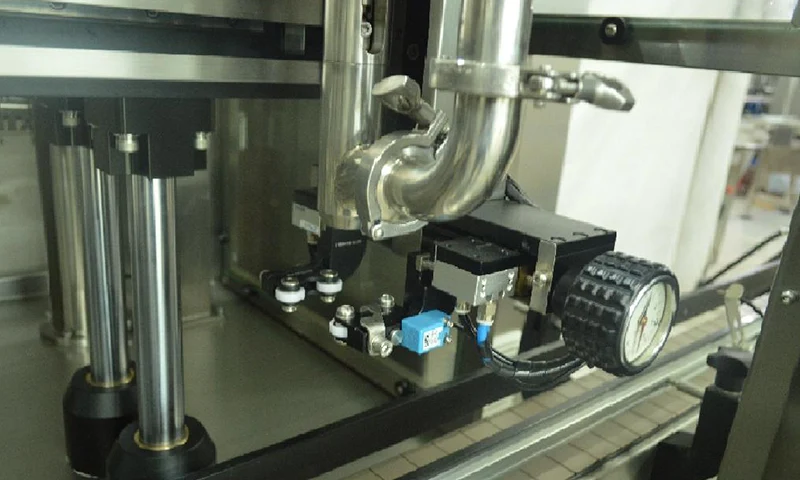

Piston Cylinder

Adopt servo control, piston filling form, PLC and man-machine control interface. With four groups of dose adjustment memory data,

The piston stroke is driven by servo motor, the stroke positioning is accurate, and the filling speed is set fast and slow.When

the filling is close to the mouth of the bottle, the speed pressure is reduced to prevent the liquid from spilling due to the

large impact.

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine