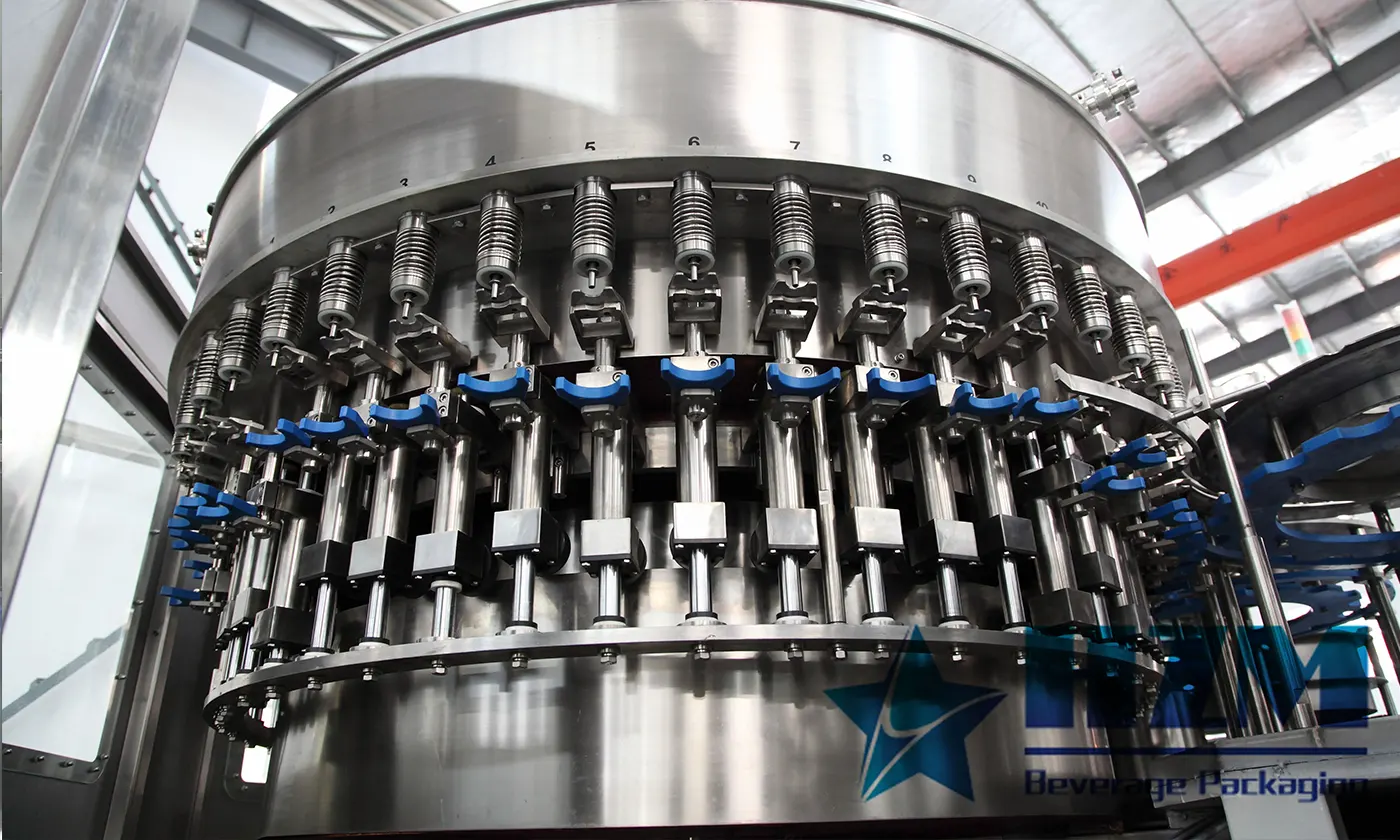

DXGF40-40-10-type isobaric filling machine is 3-in-1 filling machine which combines rinsing, filling capping in one machine. The equipment is innovated and developed based on the introduction, digestion and absorption of foreign advanced technology and according to the gas-bearing beverage filling process requirements,. It is mainly used for gas flushing, filling and capping plastic pre-threaded cap soft drinks, cola, sparkling wine, mineral water, beverages etc. The machine has reasonable structure, safe, reliable, easy to maintain and it is the ideal equipment for beverage filling factory.

Mono-block Isobaric Filling Machine

Function : Rinsing, Isobaric Filling, Capping

Applicable : Carbonated Drinks, Cola, Sparkling Water, Sparkling Wine, Soft Drinks

Capacity : 12,000–15,000 BPH (based on 500ml bottles, model DXGF40-40-10)

Bottle Type : Plastic Bottles with Pre-threaded Caps

Technology : Isobaric Filling, 3-in-1 Monoblock Design

Features : Safe, Reliable, Easy to Maintain, Compact Structure, High Automation

Application Industry : Beverage Factories, Soft Drink Plants, Bottled Water Companies, Alcoholic Sparkling Beverage Producers

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Configurations

| Item | Brand |

| Main motor + Reducer | ABB - Germany |

| Sealing rings | Busak + Shamban - Germany |

| Inverter | Siemens / Mitsubishi - Japan |

| PLC | Siemens / Mitsubishi - Japan |

| Touch screen | Siemens / Mitsubishi - Japan |

| Low pressure electrics | Schneider - France |

| Photoelectric switch | Banner / Leuze - Germany |

| Pneumatic components | SMC / FESTO - Germany |

| Sliding bearing | IGUS - Germany |

| Temperature control | Omron - Japan |

| Inlet proportional valve | SHENJI - China |

Main features

1. Compact structure, beautiful appearance, easy operation, high automation, low labor intensity

2. Bottles transmission adopts bottlenecks clamping technology, no need to adjust the equipment height when changing bottle volume, simply replace guide plate, thumb wheel that related to the bottle diameter and mouth.

3. Theparts that direct contact with product are made of SUS 316L stainless steel and no technology corner pockets

4. Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

5. High-speed high-volume, high precision filling valve, filling fast, accurate and non-liquid fluid loss.

6. Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, to ensure filling accuracy.

7. Equipped with CIP circuit and control procedures, equipment is cleaned in place.

8. Capping head adopts constant magnetic torque device to ensure the seal of quality, and will not damage caps.

9. Efficient use of the cap sorting system, with a perfect cap lacking protective device.

10. Bottle-outlet thumb wheel adopts downward spiral approach, when changing bottle volume, no need to adjust conveyor height.

11. With complete overload protection device, which can effectively protect the equipment and the operator's safety.

12. Using touch-screen operation, can realize man-machine dialogue, equipment operation status is very clear.

13. Main electrical components (touch screen, PLC, inverter, etc.) are imported brand-name products, Omron、Mitsubishi、Schneider ,etc

14. Pneumatic system components are used well-known brand name products. SMC,or FESTO ,etc

Technical parameter

1. Model: DXGF 40-40-10

2. Bottle height: 120-310mm;bottle diameter: 50-110mm

3. Air supply pressure: 0.7MPa

4. Air consumption: 1m3/min

5. Rinsing water pressure: 0.2~0.25 Mpa

6. Rinsing water consumption: 2.0T/H

7. Filling method: Isobaric filling

8. Filling temperature: ≤5℃

9. Main motor power: 7.5 KW

10. Rated voltage: 380V

11. Capacity:12000BPH 0.5L;

12. Dimension: 4360*3300*2700mm(L×W×H)

13. Weight: 8500Kg