What Is the Production Capacity of a Small-Scale Beverage Packaging Line?

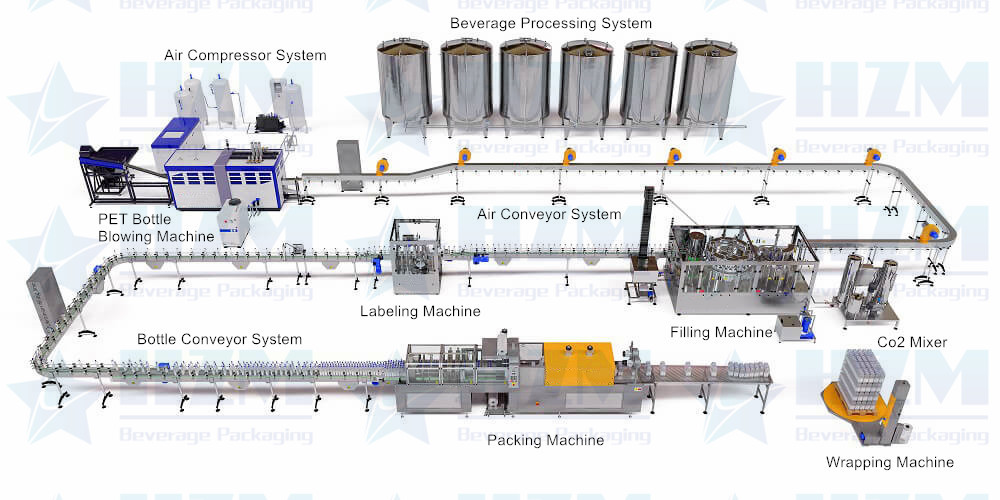

In the beverage industry—whether it's juice, tea, energy drinks, or bottled water—the production capacity of the packaging line is a core metric that defines operational efficiency. For startups, small-scale factories, or custom production workshops, choosing the right small beverage packaging line is crucial. So, what exactly is the output capacity of a small beverage packaging line? Let’s explore this question through a modern integrated machine that combines rinsing, filling, and capping into one unit.

Integrated Design for Efficient Output

This small beverage packaging line integrates bottle rinsing (with disinfectant and pure water), beverage filling, and cap sealing into a single piece of equipment. This not only saves floor space but also simplifies operations, making it an ideal solution for efficient and stable production.

Typical Output Range of a Small Beverage Packaging Line

Depending on the specific model and configuration, this equipment delivers a production capacity ranging from 6,000 to 18,000 bottles per hour (based on 500ml PET bottles). Here is a breakdown of different models and their corresponding capacities:

| Model | Rinsing-Filling-Capping Heads | Capacity (500ml) | Dimensions (mm) | Main Power |

|---|---|---|---|---|

| RXGF16-16-5 | 16-16-5 | 6,000 BPH | 2760×2060×2700 | 2.2 KW |

| RXGF24-24-8 | 24-24-8 | 8,000 BPH | 2800×2230×2700 | 3.0 KW |

| RXGF32-32-8 | 32-32-8 | 12,000 BPH | 3550×2650×2700 | 4.0 KW |

| RXGF40-40-10 | 40-40-10 | 15,000 BPH | 4360×3300×2700 | 7.5 KW |

| RXGF50-50-12 | 50-50-12 | 18,000 BPH | 4720×3545×2700 | 7.5 KW |

Key Features and Highlights

High-Precision Filling System

The machine uses a full-level filling method, effectively preventing bottle deformation after cooling and minimizing oxygen dissolution. The umbrella-type filling valve ensures rapid flow, high filling precision, and stable liquid level—with no spillage or product loss.

Intelligent Temperature Control & CIP Cleaning

Equipped with an automated temperature control system for hot filling, the equipment also features a comprehensive CIP system that thoroughly cleans pipelines and filling valves to maintain hygiene and product safety.

Efficient Rinsing System

The rinser uses EPDM sealing rings and UMPE nozzles, capable of reaching all interior surfaces of the bottle. A water-saving design with splash guards and recovery pipes ensures efficiency and eco-friendliness.

Flexible Capping Design

The capping head features a dual-purpose design, compatible with both flat caps and sports caps, making it suitable for a wide range of beverage types.

Premium Electrical Components

The equipment uses internationally renowned brands such as SIEMENS, SCHNEIDER, FESTO, and others, ensuring reliable and stable operation.

A Smart Investment for Growing Brands

Small beverage packaging lines combine flexibility, efficiency, and sanitation, making them the go-to solution for many new beverage brands and local manufacturers. Thanks to their lower investment cost and modular scalability, these systems can help businesses quickly launch and stabilize production.

Whether you’re developing a new juice product or planning large-scale production of energy drinks, a small beverage packaging line is your reliable partner for streamlined and professional output.

Interested in a customized solution based on your production needs and budget? Contact us today for detailed technical specs and a personalized quote.

TAG:

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine