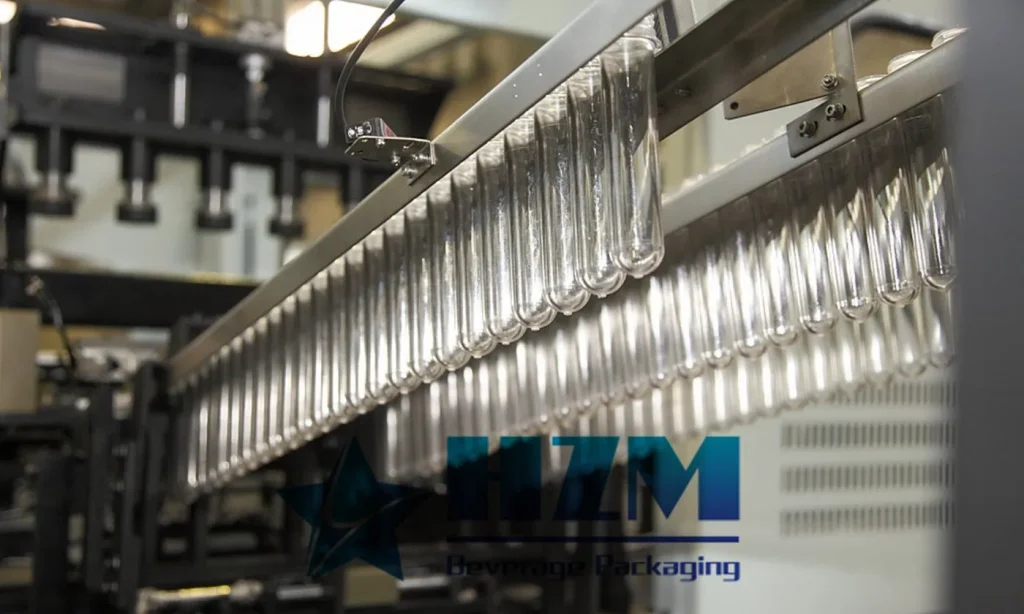

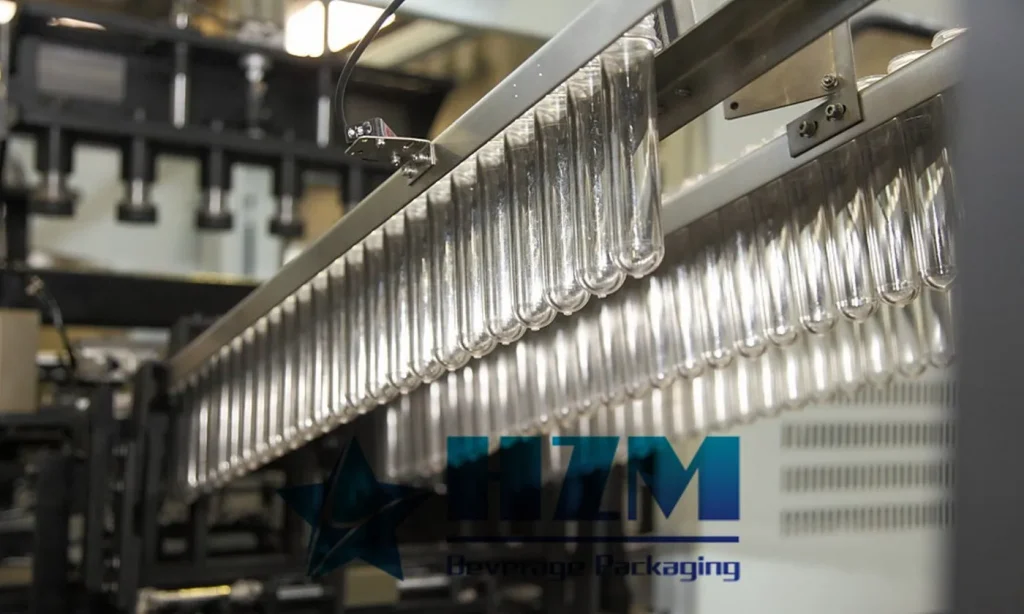

Key Factors for Choosing a High-Quality PET Bottle Blowing Machine

Choosing a high-quality PET bottle blowing machine is crucial for ensuring production efficiency and product quality. This article will discuss the key factors to consider when selecting a high-quality PET bottle blowing machine, helping you make informed decisions.

- Manufacturer Reputation and Experience: Choosing a reputable manufacturer is essential to ensure a high-quality PET bottle blowing machine. Research the manufacturer's reputation, market position, and customer reviews to understand their performance and experience in the industry. Experienced and technologically advanced manufacturers often provide more reliable and durable equipment.

- Equipment Quality and Performance: Thoroughly examine the quality and performance indicators of the PET bottle blowing machine. Pay attention to the following key aspects:

- Structural Design: Ensure the machine has a robust and stable structure, allowing for long-term reliable operation and user-friendly handling.

- Control System: Advanced control systems provide high automation and precise operation, ensuring consistent production quality.

- Transmission System: Consider the reliability and efficiency of the transmission system for smooth operation and high productivity.

- Production Capacity and Applicability: Choose a PET bottle blowing machine that matches your production needs in terms of production capacity and applicability. Consider the anticipated production volume and the required range of bottle sizes. Select the appropriate model and configuration to meet your production requirements.

- Technical Support and After-Sales Service: Select a manufacturer that offers comprehensive technical support and timely after-sales service. Ensure the manufacturer provides training, maintenance, and spare parts support to address issues promptly and maintain smooth equipment operation.

- Cost and Return on Investment: In addition to equipment quality, consider the cost and return on investment. Evaluate the equipment price, performance, durability, and expected production benefits. Strike a balance between cost and return, selecting equipment that best aligns with your needs.

- Customer References and Site Visits: Gather as many customer references and feedback as possible before making a decision. Additionally, conduct on-site visits to the manufacturer's production facilities and equipment to ensure they meet your expectations and requirements.

Conclusion: Choosing a high-quality PET bottle blowing machine is crucial for ensuring production efficiency and product quality. By selecting a reputable manufacturer, evaluating equipment quality and performance, considering production capacity and applicability, prioritizing technical support and after-sales service, balancing costs and returns, and referencing customer feedback and conducting site visits, you can choose the most suitable high-quality PET bottle blowing machine for your needs.

TAG: PET Bottle Blowing Machine

-

![Raw Water Treatment System for Beverage Plant]()

Raw Water Treatment System for Beverage Plant

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line