Carbonated Soft Drink (CSD) Filling Machine

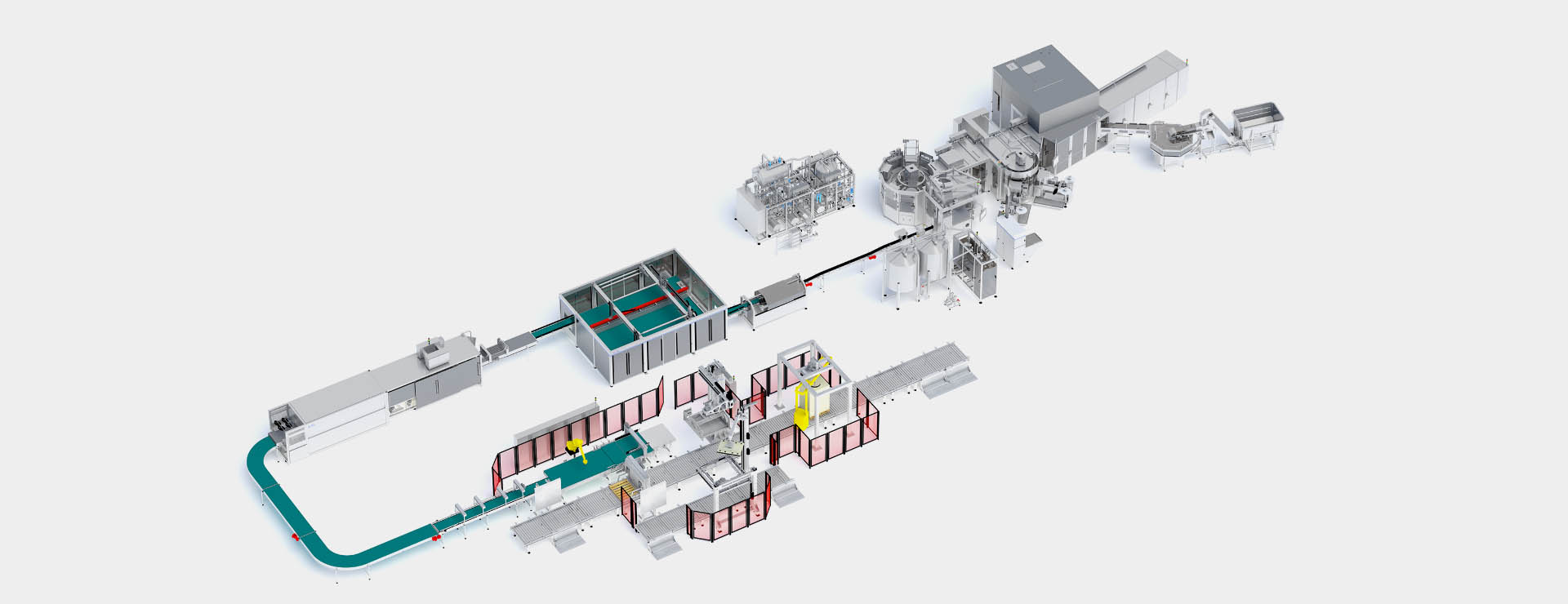

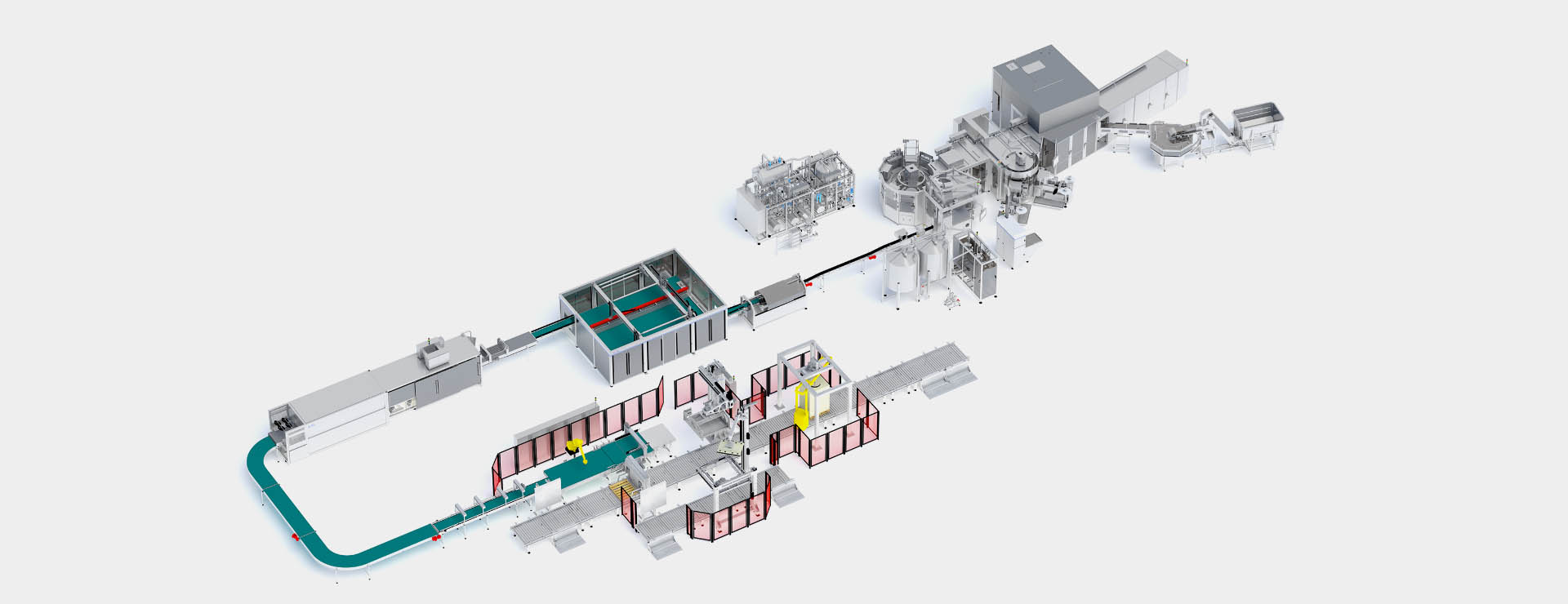

A Carbonated Soft Drink (CSD) Filling Machine is a piece of equipment used in the beverage industry for filling carbonated soft drinks (such as sodas, colas, and other fizzy beverages) into containers like bottles or cans. These machines are designed to handle the specific requirements of carbonated beverages, including maintaining proper carbonation levels, preventing foaming, and ensuring accurate filling to avoid spillage and wastage.

CSD Filling Machines are typically automated or semi-automated systems that can fill a large number of containers quickly and consistently. They often include components like bottle rinsers, filling nozzles, carbonation systems, and capping or sealing stations to complete the packaging process. These machines are crucial in ensuring the efficient production of carbonated beverages and maintaining product quality and consistency.

Features and Pricing

Prices vary depending on the manufacturer, model, and features, typically ranging from a few thousand dollars to several hundred thousand dollars. Selecting a machine that fits your production needs and budget is crucial. HZM Machinery offers you more competitive prices. Please feel free to contact us anytime to get a quote.

1.By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

2.The parts that direct contact with product are made of SUS 316L stainless steel and no technology corner pockets.

3.Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

4.Periodical gas exhaust and fast and slow snifting prevent product foaming.

5.Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

6.Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, ensure filling accuracy.

7.Simple internal filling valve chamber without springs ensure thorough cleaning & sanitation. Automatic CIP cups are highly efficient.

8.The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

9.All control is advanced touch-screen operation and realize people-computer dialogue operation.

Usage Considerations

When using CSD Filling Machines, consider the following:

- Operator Training: Ensure operators receive proper training to ensure safe operation and optimal performance.

- Maintain Cleanliness: Keep the filling machine clean to prevent contaminants from entering the beverage and to prolong the machine's lifespan.

- Regular Inspection: Periodically inspect all machine components to ensure they are functioning correctly, reducing downtime and potential failures.

- Safety Standards: Adhere to all relevant safety standards and regulations to ensure the safety of operators and equipment.

Maintenance and Upkeep

CSD Filling Machines require regular maintenance and upkeep to ensure performance and longevity:

- Lubrication: Regularly lubricate moving parts of the machine to reduce friction and wear.

- Replace Consumables: Timely replacement of consumables such as seals, pipes, and valves is essential.

- Cleaning System: Periodically clean and sanitize the filling system to maintain beverage hygiene.

- Regular Calibration: Calibrate carbonation control systems as needed to maintain beverage consistency.

Common Troubleshooting

Although CSD Filling Machines are typically reliable, occasional malfunctions may occur. Here are some common issues and troubleshooting steps:

- Carbonation Control Failure: Check the carbonation control system to ensure it's operating correctly and calibrate if necessary.

- Overflow: Adjust machine settings to ensure proper liquid levels and prevent overflow.

- Mechanical Failure: Immediately shut down and power off the machine, then contact a maintenance professional for inspection.

- Electrical Issues: Disconnect power and inspect wiring and electrical components; repair faults or replace damaged parts.

In summary, CSD Filling Machines are crucial tools for the production of carbonated soft drinks, improving production efficiency, ensuring product quality, and meeting market demands. By following proper usage and maintenance guidelines, these machines can be reliable and long-lasting, providing significant benefits to beverage manufacturers.

TAG: Carbonated Soft Drink Filling Machine CSD Filling Machine Sparkling Water Filling Machine

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?