The Carbonated Soft Drink Filling Machine is primarily used for washing, filling, and capping in the production lines of carbonated drinks and mineral water. This equipment is suitable for the production of carbonated beverages in PET bottles, glass bottles, and cans of various shapes.

Machinery Capacity:4000BPH~28000BPH

As a professional packaging equipment manufacturer, we offer factory-direct prices to ensure affordability. Additionally, we have a team of professional after-sales service engineers who can provide on-site installation and training services.

How To Ensure The Quality Of Carbonated Filling Machine?

Our warrantee time is 2 years after installation and commissioning, within 2 years the machines get quality problem, we will take full responsibility and provide services.

Carbonated Soft Drink Filling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Product Configurations

| Model | DXGF14-12-5 | DXGF16-16-5 | DXGF24-24-8 | DXGF32-32-8 | DXGF40-40-10 |

| Capacity (for 500ml) |

3,000BPH | 5,000BPH | 8,000BPH | 12,000BPH | 15,000BPH |

| Bottle diameter | 50~110mm | ||||

| Bottle height | 160~310mm | ||||

| Air source pressure | 0.7MPa | ||||

| Main motor power |

1.5KW | 2.2KW | 3.0KW | 4.0KW | 7.5KW |

| Dimension | 2360*1770*2700 | 2760*2060*2700 | 2800*2230*2700 | 3550*2650*2700 | 4360*3300*2700 |

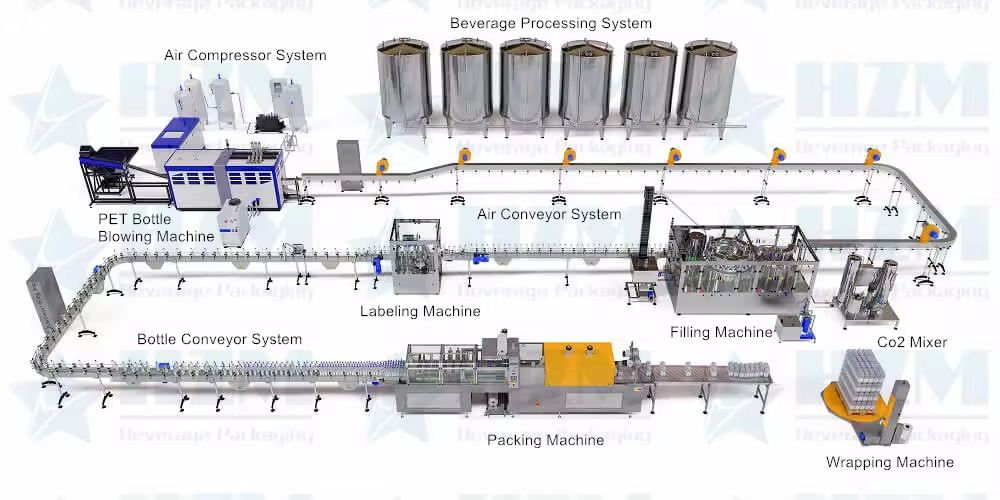

Complete Carbonated Soft Drink Filling Production Line

Product Features

1. The all carbonated drinks filling machine parts directly contacted with media are all adopted with food stage stainless steel without dead angle, so they can be cleaned easily.

2. The carbonated drinks beverage fillling machine uses the deflection adjustment, the continuous-type control material fluid liquor flux, causes fluid position of the hydraulic cylinder maintenance smaller undulation, guarantees filling precision.

3. Operating valve institution actuated by the air cylinder, according to bottle signal promptly to operate the valve, the movement accurate and reliable.

4. High filling speed and mass flow rate, high precision of filling valve and control of liquids level is accurate and without loss.

5. The carbonated drinkks filling machine is carried perfect CIP control loop and program and cleaning devices on the spot.

6. The filling machine capping head is adopted magnetic-constant-torque device to ensure the high capping quality and without damages.

7. The carbonated drinks beverage fillling machine adopts efficient cap settling system which carried perfect cap feeding and protection device.

8. The carbonated drinks beverage fillling machine is adopted spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel. And to adjust the input height is not necessary for exchanging model of bottle.

Carbonated Soft Drink Filling Machine Equipment Details Display

Rinsing Part

1. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

2. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall,

saving rinsing water.

3. Covering of bottle clamps and elevator are product of Igus.

Filling Part

1. Each filling valve is equipped with an air return channel independent of the liquid cylinder. The replaced air in the PET bottle does not enter the liquid cylinder during the filling process.

2. The filling valve is equipped with a cleaning cup, which can thoroughly CIP cycle clean the filling valve.

3. Adopt lifting cylinder bottle lifting mechanism, using bottle clamp technology to avoid pollution.

Capping Part

1. Adopt magnetic constant torque screw cap head, and the screw cap effect is stable and reliable.

2. The fall guide rail has the device to prevent the reversal cap from passing and pick out the reversal cap.

3. It has the bottle check-up switch to control the cap flow and stop it in case no bottle to reduce the cap quantity.

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine