Water Filling Production Line: Efficient, Safe, and Stable Industry Solution

The water filling production line is a crucial equipment in the modern chemical industry, used for efficient, safe, and stable filling and packaging of water or other liquid products. This article will provide a detailed overview of the structure, characteristics, advantages, production standards, and safety measures of the water filling production line. It aims to help readers gain a comprehensive understanding of the importance and application of this industry solution.

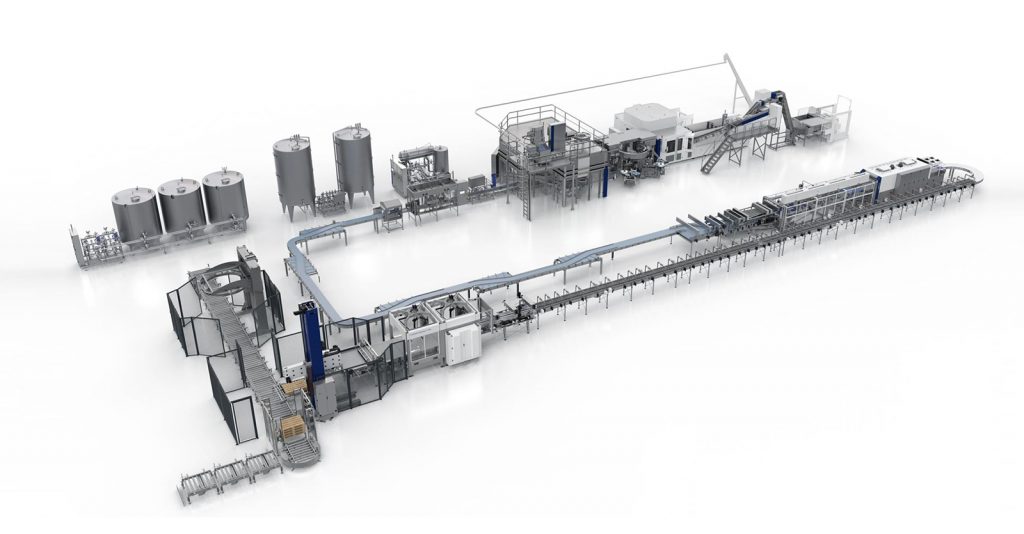

- Structure and Working Principle: The water filling production line typically consists of the following main components:

- Conveyor System: Used to transport empty bottles or containers from the starting point to different workstations, including conveyor belts, transfer wheels, etc.

- Filling Unit: Through a high-precision filling device, water or other liquid products are accurately injected into the containers, ensuring consistency and accuracy in the filling volume.

- Sealing Unit: Used to seal the filled containers to ensure product sealing and safety.

- Labeling System: Automatically attaches labels to the containers for identification and recognition of the products.

- Packaging System: Packages and boxes the filled products for storage, transportation, and sales.

- Characteristics and Advantages: The water filling production line possesses several important characteristics and advantages in the modern chemical industry, including:

- High Production Efficiency: The water filling production line employs automated control and high-speed operations, enabling large-scale production to improve efficiency and output.

- Filling Accuracy: Equipped with high-precision filling devices and flow control systems, it ensures consistent and accurate filling in each container, avoiding wastage and inconsistent filling.

- Flexibility and Adaptability: The water filling production line can be adjusted and configured to accommodate different bottle types, capacities, and product variations, catering to diverse market demands.

- Quality Control: The production line is equipped with quality inspection and monitoring devices, enabling real-time monitoring and control of product quality to ensure compliance with standards and specifications.

- Stable Operation: With advanced automation control systems and stable mechanical design, the water filling production line operates reliably and minimizes the risks of malfunctions and downtime.

- Production Standards: The production standards of the water filling production line typically depend on the specifications and configuration of the equipment. Standard configurations of the production line can achieve filling and packaging of thousands to tens of thousands of containers per hour. The production capacity can be further customized and expanded based on industry requirements.

- Safety and Hygiene: The water filling production line incorporates several measures to ensure product quality and consumer safety:

- Material Selection: The production line utilizes materials that comply with hygiene standards, such as stainless steel and food-grade plastics, ensuring hygiene and safety of the products.

- Cleaning and Sanitization: The production line is equipped with automated cleaning and sanitization systems, regularly cleaning and disinfecting the equipment to prevent cross-contamination and bacterial growth.

- Inspection and Screening: The production line is equipped with quality inspection devices and screening systems to detect and remove foreign particles and defective products, ensuring that only high-quality products enter the market.

- Operator Training: Operators receive necessary training and guidance to understand operating procedures and hygiene requirements, ensuring adherence to operational norms and hygiene standards.

Conclusion: The water filling production line is an indispensable equipment in the modern chemical industry. Its efficiency, safety, and stability make it the preferred solution for the filling and packaging industry. By enhancing production efficiency, ensuring product quality and safety, the water filling production line provides significant competitive advantages for businesses, promoting industry development and progress.

TAG: Water Filling Line Water Filling Machine

Automatic Drinking Water Filling Production Line Equipment

Automatic Mineral Water Bottle Filling Machine: The Ideal Choice for Efficient Production

Unveiling the Secrets of Efficient Beverage Production Line Equipment

How Much Does a Small Bottled Purified Water Production Machine Cost?

How much does a set of bottled water production line equipment cost?

Comprehensive Analysis of Bottled Water Production Line

3 Key Principles to Consider When Purchasing Filling Machines

Operating Steps and Precautions for Small Bottle Water Filling Machine

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine