Edible Oil production process

The edible oil production process is a multi-stage operation that involves extracting oil from oilseeds, refining it, and packaging it for sale.

1.Seed Preparation:

The process begins with the selection and cleaning of oilseeds (such as soybeans, sunflower seeds, or palm fruits).

Seeds are cleaned to remove impurities and foreign materials.

2.Oil Extraction:

Mechanical pressing or solvent extraction methods are commonly used to extract oil from seeds.

Mechanical pressing involves using an expeller press to physically squeeze the oil out of the seeds.

Solvent extraction uses chemicals like hexane to dissolve the oil from the seeds.

3.Oil Refining:

The crude oil extracted undergoes refining processes to remove impurities, color, odor, and undesirable components.

Refining may involve degumming, neutralization, bleaching, and deodorization.

4.Degumming:

Removes phospholipids from the crude oil.

5.Neutralization:

Neutralizes free fatty acids in the oil.

6.Bleaching:

Removes pigments, residual soap, and other impurities.

7.Deodorization:

Removes volatile components that cause odor and flavor in the oil.

8.Fractionation:

Separates the oil into different fractions, such as liquid oil and solid fat, based on their melting points.

9.Packaging and Storage:

The final refined oil is packaged and stored for distribution.

TAG: Edible Oil Filling Machine Oil Filling Machine

Analysis of Reasons for Inaccurate Counting of Flowmeter in Edible Oil Filling Machine

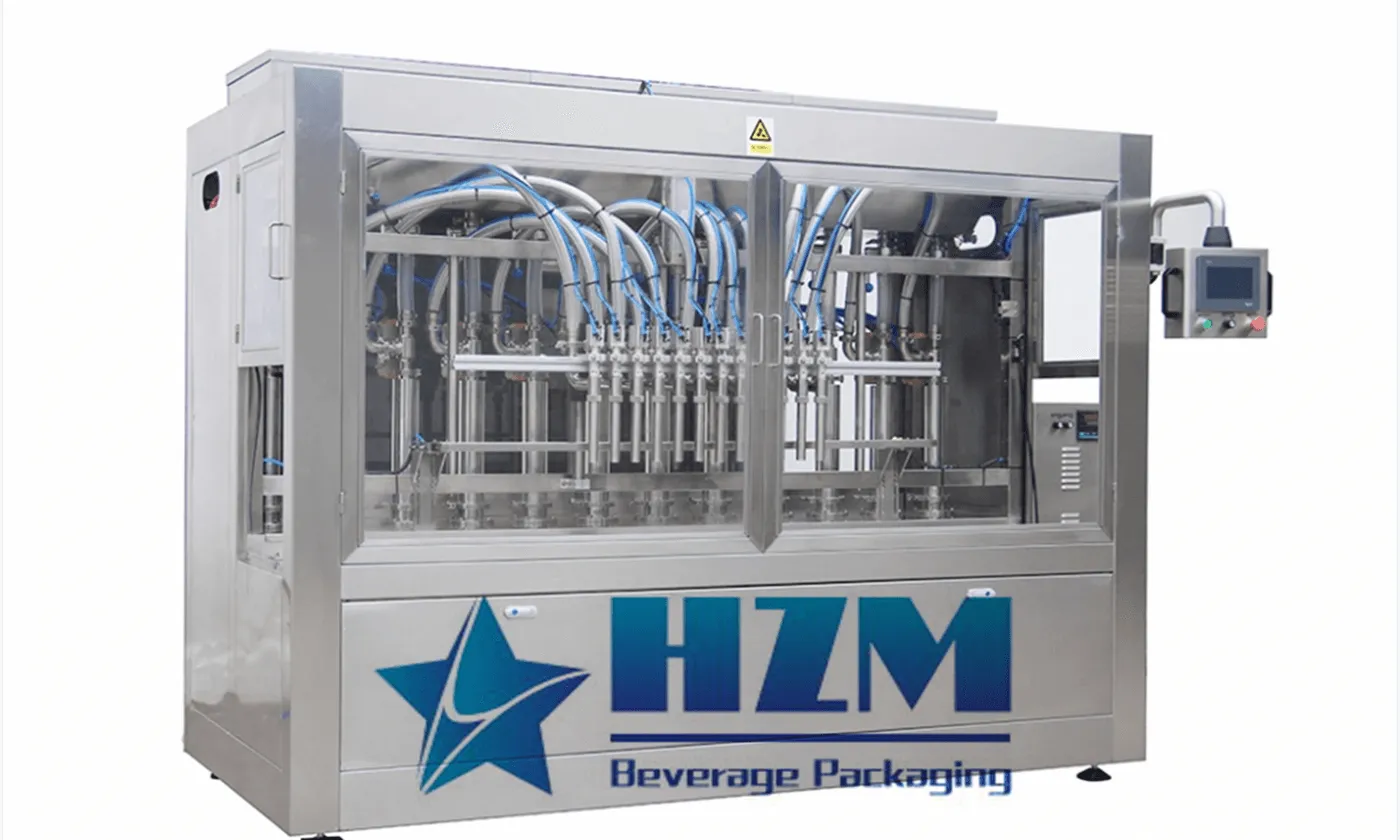

Manufacturer of edible oil filling machines offers stable and user-friendly equipment

Introduction to the Edible Oil Filling Production Line

Edible Oil Production Line Equipment and Costs

Choosing Quality Cooking Oil: Tips from Edible Oil Filling Machine Manufacturer

The Trend Towards Automation and Intelligence in Edible Oil Filling Machines

Addressing the Leakage Problem of the Edible Oil Filling Machine’s Filling Head

How to Perform Maintenance on Edible Oil Filling Machine with Oil Leakage

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine