Selling a complete automated production line for carbonated cola beverages.

Our company offers a range of complete production line equipment for carbonated cola beverages, categorized based on production speed as follows: small-scale (2000 bottles/hour), medium-scale (4000 bottles/hour, 7000 bottles/hour), and large-scale (10000 bottles/hour, 15000 bottles/hour to 36000 bottles/hour). Customers looking to procure carbonated beverage equipment can provide bottle specifications, capacity, and production speed, and we can assist in designing a tailored solution to support your factory setup.

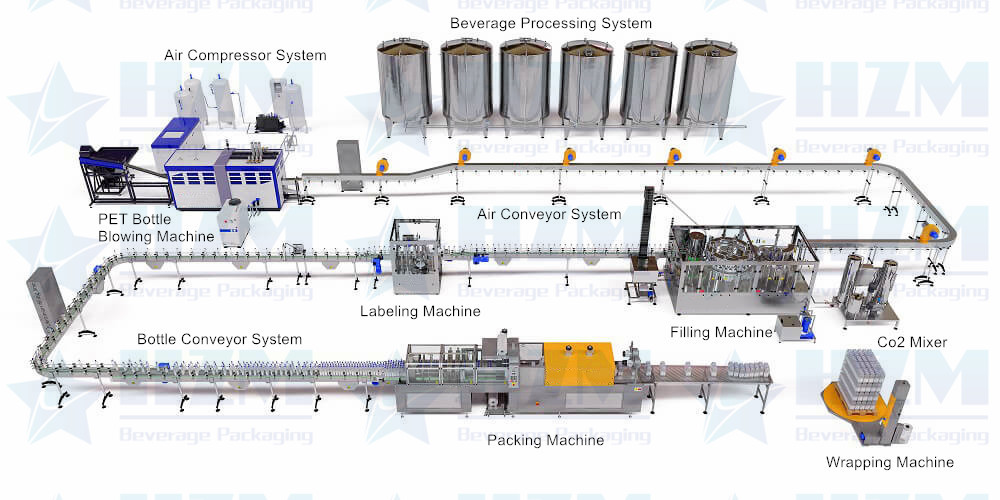

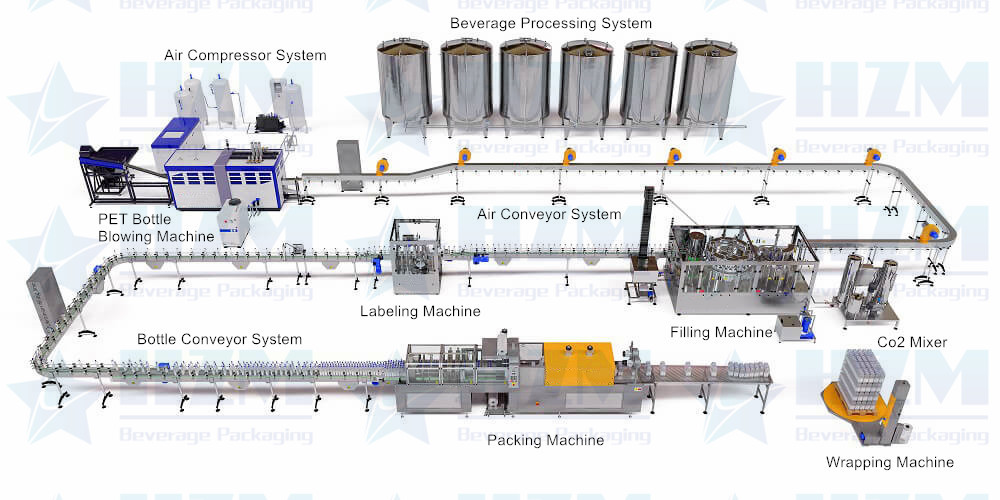

The fully automated carbonated cola beverage production line includes the following main equipment: water treatment equipment, sugar melting tank, ingredient tanks, dual-filter, chiller, plate heat exchanger, beverage mixer, carbon dioxide filter, three-in-one rinsing, isobaric filling equipment, capping equipment, bottle warmer, high-pressure air dryer, inkjet coder, labeling machine, PE film heat shrink packaging machine, or carton packaging machine, and a tape sealing machine, among others.

This equipment is suitable for filling and producing beverages with carbon dioxide gas in various bottle capacities, such as 350ml, 500ml, 1L, and 1.5L, including well-known beverage brands like Coca-Cola, Fanta, and Sprite. If plastic bottles with the same neck diameter specification are used, different bottle capacities can be accommodated with a single three-in-one isobaric filling machine. The equipment parts that come in contact with materials are made of high-quality 304 stainless steel, providing corrosion resistance and ease of cleaning. In terms of electrical control, we primarily utilize PLC and frequency converters for machine control, with a user-friendly interface for high automation and easy operation.

Based on the operating speed of the filling machine, with 500ml bottle capacity as the reference, our three-in-one isobaric filling machine is available in several configurations, ranging from 2000 bottles/hour, 4000 bottles/hour, 7000 bottles/hour, 12000 bottles/hour, and 18000 bottles/hour to 36000 bottles/hour.

The operating principle of the carbonated beverage filling machine is as follows: for glass bottles, a bottle bottom conveying method is used, which may have a slightly higher equipment cost compared to plastic bottle filling. Glass bottles are first divided by a screw and then enter the bottle washing mechanism, where bottles are gripped at the neck, inverted 180 degrees, and rinsed both internally and externally using purified water. The rinse water is collected and discharged through a designated outlet. The rinse water for glass bottles needs to be preheated to avoid bottle breakage due to temperature differences and requires an additional heat exchange device. This rinsing step is intended to remove minor airborne particles from inside the glass bottles. If recycled glass bottles are used, they need to be disinfected and thoroughly cleaned before entering the carbonated beverage filling machine.

Once the washing process is completed, the glass bottles move to the isobaric filling mechanism. The bottles slowly rise and make contact with the sealing gasket below the isobaric filling valve. Inflating begins, and when the internal pressure of the bottle matches the internal air pressure of the cylinder, carbonated beverage filling commences, ensuring no foaming occurs. After a specific time, the upper fork is closed, stopping inflation. Under pressure differential, the filling valve automatically closes, and the filling process ceases. However, before the bottle neck leaves the valve, a device releases any trapped gas to prevent carbonated beverage spilling. After releasing the gas, the entire isobaric filling process is considered complete, and the bottles move on to the capping mechanism. Glass bottles for carbonated beverages typically use crown caps, providing an excellent seal. The entire capping mechanism operates in a cylindrical fashion, rotating 360 degrees around the central spindle. As bottles with caps move under the capping head, it presses the caps tightly in place. The bottles are then conveyed by the chain plate to complete the entire process, including washing, filling, and capping.

TAG: carbonated beverage production line Carbonated Drinks Filling Machine Carbonated Filling Machine

-

![Raw Water Treatment System for Beverage Plant]()

Raw Water Treatment System for Beverage Plant

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line