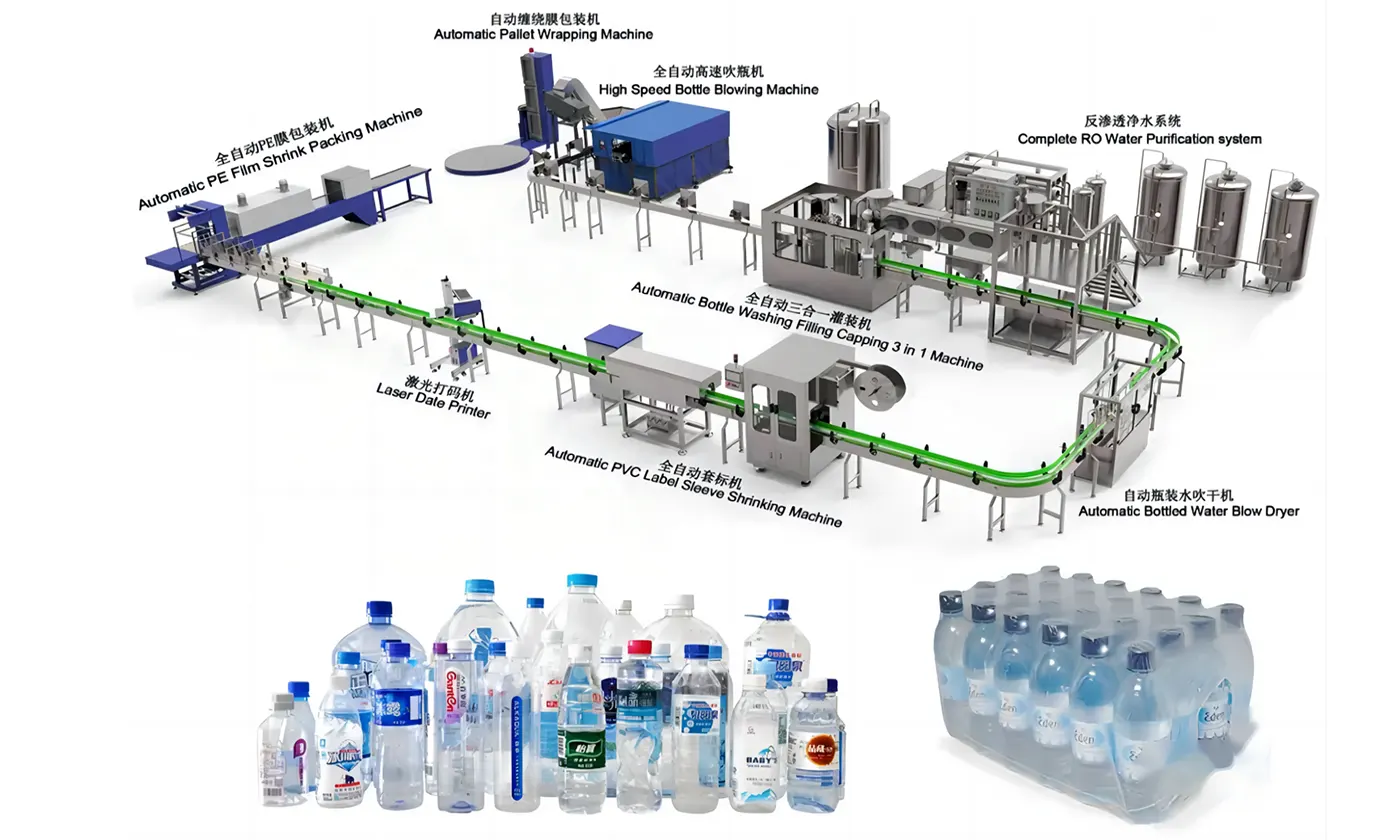

The process flow of mineral water production line

The production process of the mineral water production line includes mineral water treatment equipment, mineral water bottle blowing machine, fully automatic mineral water filling machine, bottle cap disinfection machine, mineral water labeling machine, mineral water coding machine, mineral water packaging machine, conveyor lines, connecting pipelines, etc.

The mineral water filling machine is responsible for three main functions: rinsing, filling, and capping empty bottles. It is suitable for producing bottled drinking mineral water in sizes ranging from 350ml, 500ml, 1L, 1.5L, to large bottles of 4L-15L capacity.

The components of the small bottle mineral water filling machine and mineral water production line equipment include water treatment systems, automatic bottle blowing machines, pneumatic conveyors, cap sterilizers, cap cleaning machines, bottle filling and capping machines, drying machines, labeling machines, coding machines, palletizers, wrapping machines, bottle conveying systems, box conveying systems, and electrical control systems. Optional equipment includes automatic bottle arranging machines or manual bottle arranging systems, full/half automatic bottle washing machines, labeling machines, carton packaging machines, nitrogen machines, etc. Production capacity: Our company has formed a complete series of product lines, ranging from 2,000 bottles/hour to 36,000 bottles/hour (calculated with 500ml PET bottles).

In terms of assembly precision, the entire tabletop, also known as the installation plane, is machined with a gantry milling machine to remove about 5mm. Then, based on the processed plane, various spindle holes are machined on the bed. The purpose of this process is to ensure the flatness of the tabletop, the specific position and parallelism of each spindle centerline, as well as the perpendicularity to the tabletop, thereby ensuring the installation accuracy of the mineral water three-in-one filling machine. Here's a reminder: Some manufacturers omit the above machining process to reduce equipment costs and rely on adding adjusting shims to ensure assembly accuracy. However, this approach may lead to a series of after-sales problems. Over time, the shims may shift due to machine vibration, reducing the overall assembly accuracy of the machine and causing it to malfunction, thereby increasing a series of after-sales service costs. Producing machines according to our regular machining process not only ensures the stability of the three-in-one filling machine but also avoids unnecessary after-sales service, achieving a win-win situation for both the manufacturer and the user.

Regarding materials, all parts in contact with water are made of 304 stainless steel, and the entire frame and door panels are also made of 304 stainless steel. In terms of electrical control, variable frequency drives (VFDs) and PLCs are mainly used. We do not place the electrical control part inside the three-in-one filling machine but use a separate control box, which is treated with moisture-proof sealing and installed with a ventilation system for cooling. In actual production, the environment is relatively humid. This separate design ensures that the electrical components will not short-circuit due to moisture, resulting in long service life, safe operation, and stable operation. An operation interface is installed on the control box to set internal parameters of the mineral water filling machine. During the operation of the filling machine, monitoring components such as photoelectric sensors, proximity switches, and liquid level detectors installed in the filling machine will feedback real-time operating parameters and display them on the human-machine interface. By using a frequency control knob, the operating speed of the mineral water filling machine can be adjusted arbitrarily. If a problem occurs with the machine, it will automatically diagnose and display the location of the fault and propose a solution. Therefore, the operation of the whole machine is very simple and convenient, achieving automated control.

TAG: Water Filling Machines Water production Line

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?