What Does It Take to Build a Mineral Water Production Line?

Mineral water is a fast-moving consumer product, particularly in the summer. Establishing a small-scale mineral water production line for a thriving business requires the following conditions:

First and foremost, a suitable location is needed. Depending on the scale of production, such as 2000 bottles per hour of beverages or water, a minimum facility size of 600 square meters is required. It should also be situated near a water source.

- Water Treatment Equipment: Reverse osmosis equipment for filtering mineral water, with a cost ranging from 40,000 to 60,000 units.

- Filling Machine: If the daily production requirement is around 1000 units and overtime production is possible, a rotary filling line with a capacity of 1000-1500 bottles per hour is sufficient. Small-scale mineral water enterprises often choose filling machines from Chenyu Machinery due to comprehensive after-sales service and customizable options based on requirements.

- Equipment Material and Key Components: To ensure durability, equipment should be constructed using 304 or 316 stainless steel. Additionally, pipes, valves, pumps, and other components with low failure rates should be of high quality.

- Bottle Blowing Machine: This is the first step in the production line, responsible for blowing mineral water bottles. The quality of this equipment directly affects the performance of subsequent machinery. Any malfunction can lead to a halt in the entire production line.

- Labeling and Packaging Machine: Labels and packaging are applied to the produced mineral water bottles, followed by cartoning.

- Facility Height: A factory with a height of over 4 meters and an area of over 700 square meters is desirable for a single production line.

- The approximate cost of fully automatic beverage filling production equipment is around 300,000 units. However, auxiliary facilities such as factory renovations, capping machines, personnel disinfection facilities, clean rooms, laboratories, etc., can add up to another 300,000 units.

- Additional expenses include rent and contingency funds.

- Therefore, establishing a beverage factory capable of producing stable quality and sustaining operations requires at least 1 million units.

- It's important to note that once the venture begins, there's no turning back. Investors in small-scale beverage enterprises often focus solely on equipment investment costs and overlook supporting facilities, auxiliary costs, startup expenses, QS certification, mold customization, employee insurance, packaging design, plate making, recruitment, training, trial production, and subsequent time and cost investments. It's advised to develop multiple plans and contingency measures and to proceed with caution.

HZM Machinery's mineral water production line utilizes world-class technology and is independently developed. It incorporates numerous new techniques, processes, and structures to achieve exceptional quality. Bottles are held between the bottle fixing plate and the upper forming plate, flipped by clamps driven by a star wheel, enabling the cleaning, filling, and sealing processes. Additionally, all parts in contact with the liquid are made from 304 stainless steel or food-grade engineering plastics, providing wear and oxidation resistance. The electrical system largely features imported components. This machine boasts standard food hygiene, stable and reliable performance, low failure rate, full automation, and comprehensive after-sales service, making it a popular choice among domestic and international customers. It's the ideal equipment for various beverage production enterprises.

TAG: 380V Mineral Water Production Line Water Bottle Filling Machine Water production Line

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

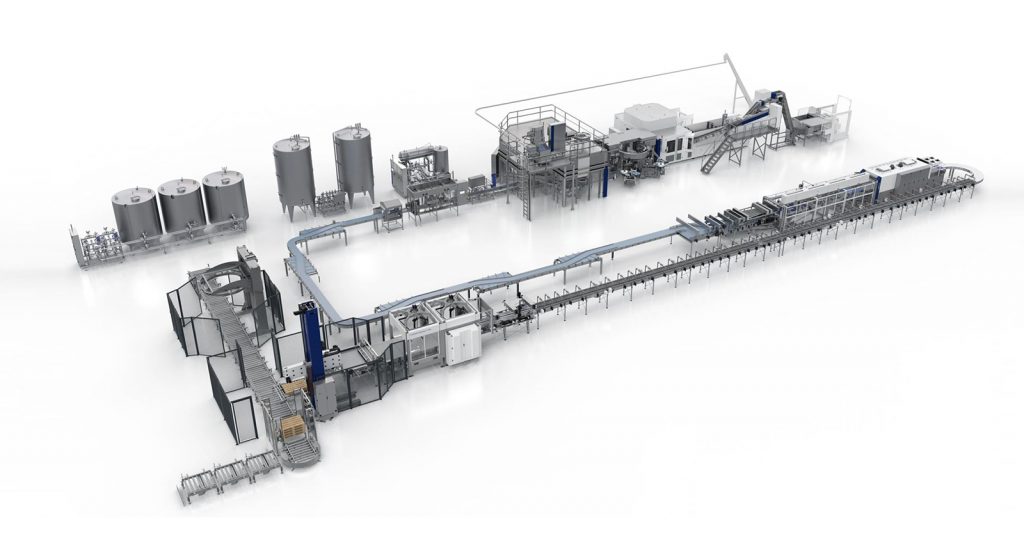

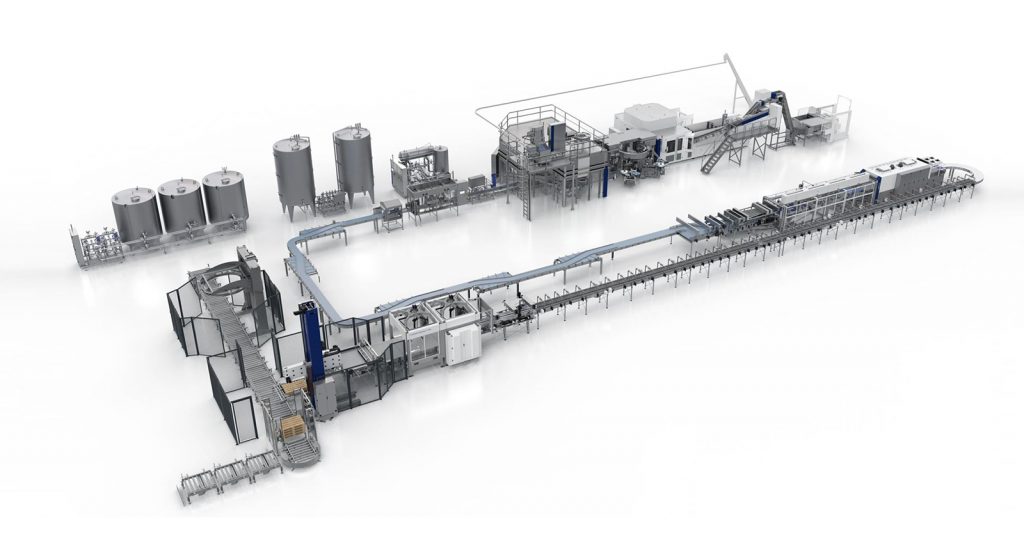

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?