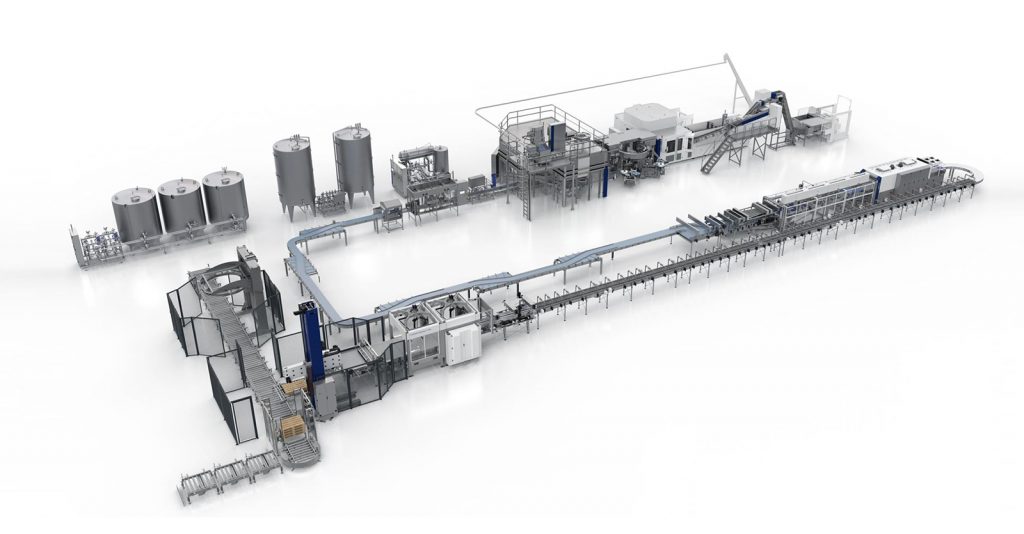

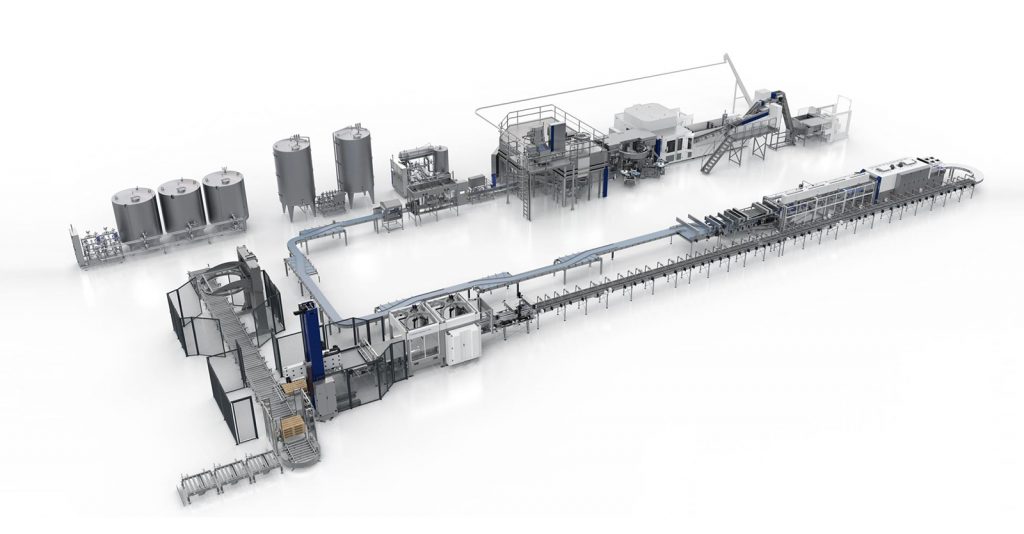

Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling Line

The design, installation, commissioning, production, and maintenance of a water bottle filling line typically involve the following steps and considerations:

Design Phase:

- Requirement Analysis: Understand the customer's needs and requirements, including production capacity, bottle specifications, filling volumes, etc.

- Process Design: Determine the workflow of the production line, including bottle feeding, cleaning, filling, sealing, packaging, etc.

- Equipment Selection and Layout: Choose appropriate equipment and machines and determine their layout and sequence on the production line.

- Control System Design: Design the automation control system of the production line, including sensors, actuators, PLCs, etc., to ensure accuracy and stability of operations.

Installation Phase:

- Equipment Procurement: Purchase suitable equipment and machines based on the design requirements.

- Equipment Placement: Install the equipment in designated positions according to the factory's layout, ensuring reasonable spacing and connections between the devices.

- Electrical Wiring: Carry out electrical wiring and connections to ensure proper power supply and communication for the equipment.

- Pipeline Connection: Connect water sources, air sources, and other necessary pipelines based on the process flow to ensure fluid supply and discharge.

Commissioning Phase:

- Parameter Settings: Configure equipment parameters according to filling requirements, such as filling volume, filling speed, sealing force, etc.

- Operational Testing: Run the equipment and perform functional tests for each step to ensure proper operation according to the design requirements.

- Troubleshooting: Detect and resolve any potential issues and malfunctions during the commissioning process to ensure equipment stability and reliability.

Production Phase:

- Operator Training: Provide training to operators to familiarize them with the operational procedures, equipment usage, and troubleshooting.

- Production Planning: Develop production schedules and ensure the production line operates according to the plan, meeting output and quality requirements.

- Process Monitoring: Monitor the production line's performance, including equipment status, production efficiency, and product quality, and make timely adjustments and optimizations.

Maintenance Phase:

- Preventive Maintenance: Establish a regular inspection and maintenance plan for the equipment, including cleaning, lubrication, and replacement of worn-out components, to prevent failures and extend equipment lifespan.

- Fault Repair: Promptly diagnose and repair equipment failures to minimize production line downtime and losses.

- Data Analysis: Collect and analyze production data to optimize production efficiency and quality, and improve the overall performance of the production line.

Please note that specific design, installation, commissioning, production, and maintenance steps may vary depending on the type of water bottle filling line and manufacturer. The provided steps serve as general guidelines and should be adjusted and supplemented based on specific circumstances.

TAG: Water Bottle Filling Line Water Bottle Filling Machine

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?