Automatic Blow Molding Machines: Unveiling the Secrets of Bottle Formation

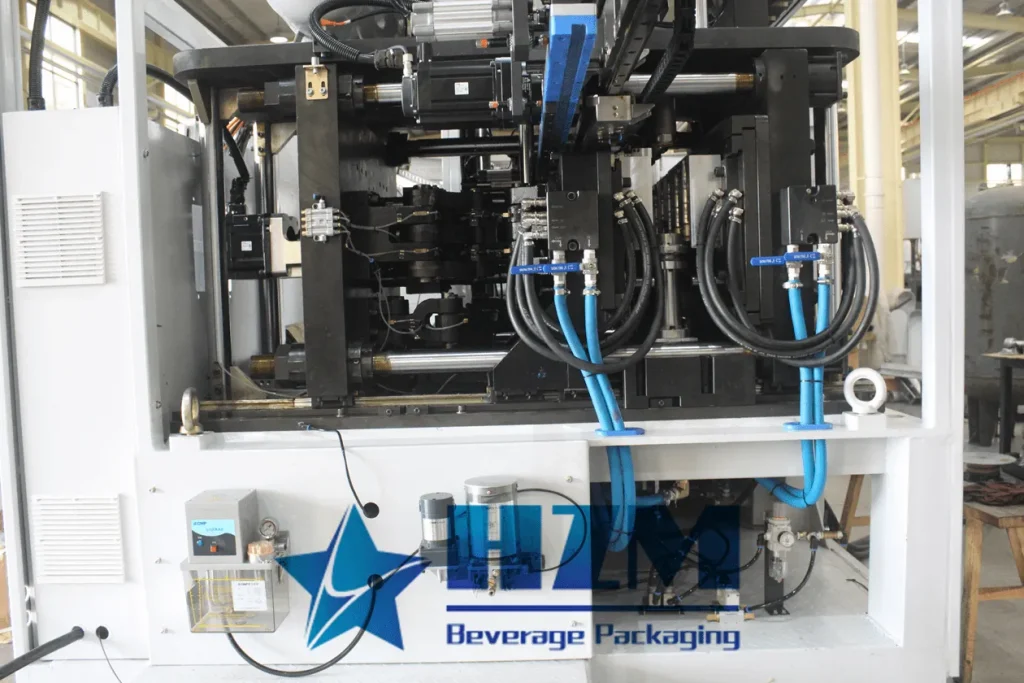

Currently, our company offers a range of bottle blowing machine equipment to meet market demands. These include the Automatic Blow Molding Machine, 5 Gallon Bottle Blow Molding Machine, PET Bottle Blowing Machine, and Rotary Blow Molding Machine.

These machines are primarily suitable for industries such as drinking water, carbonated beverages, fruit juice, tea, and dairy products. If you have any specific product requirements, please feel free to contact us at any time to obtain quotations and product information. We are more than happy to assist you.

blow molding machine refers to a device used for blowing bottles. It is a machine that can transform plastic granules (softened into liquid) or preform blanks into bottles through specific processes. The fully automated blow molding machine offers convenience, speed, and high production capacity. It has replaced manual bottle blowing in most beverage companies

1. Blow Molding Machines Introduction

A blow molding machine is a device that uses blow molding technology to produce hollow plastic containers. Common types of machines include single-step extrusion blow molding machines using PP and PE, two-step injection stretch blow molding machines using PET, PC, or PP, and newly developed machines for multilayer extrusion blow molding and stretch blow molding.

Most blow molding machines are still two-step machines, which means that the plastic material must first be made into a preform before the blowing process. The most commonly used material today is PET, an environmentally friendly plastic. Blow molding machines are a type of blow molding machine that uses hydraulic pressure. Thermoplastic resin, obtained by extrusion or injection molding, is formed into a tubular plastic preform. While still hot (or heated to a softened state), it is placed in an open mold and immediately filled with compressed air in the preform, causing the plastic preform to expand and adhere tightly to the inner wall of the mold. After cooling and demolding, various hollow products are obtained.

2. Characteristics

Plastic hollow containers are widely used in the beverage, pharmaceutical, cosmetics, food, and chemical industries due to their lightweight, low cost, and high safety. They have attracted many manufacturers to choose plastic containers instead of traditional glass containers. With the most advanced equipment, molds, and materials showcased in the plastic industry, new technologies and applications emerge endlessly, resulting in fruitful achievements in the field of plastic hollow forming. As global petroleum prices soar and plastic raw material prices remain high, the development of low energy consumption and material-saving alternative products has become a market trend.

The use of oil-free bladder locking technology provides a strong locking force, and the elbow joint has less stress and a longer lifespan. The patented flying sealing technology makes sealing, especially for wide-mouth bottles, easier.

3.Process History

Enoch Ferngren and William Kopitke were the first to validate the blow molding process. The principle of this process originated from glassblowing. In 1938, Ferngren and Kopitke manufactured a bottle-blowing machine and sold it to the Hartford Empire Company. This marked the beginning of commercial blow molding. In the 1940s, the variety and quantity of plastic products were very limited, so blow molding technology developed rapidly only much later. With the increase in product types and improved productivity, plastic products made through blow molding quickly became more abundant. In the soft drink industry in the United States, the number of plastic containers grew from zero in 1977 to 10 billion in 1999.

During World War II, blow molding began to be used for producing low-density polyethylene bottles. In the late 1950s, with the advent of high-density polyethylene and the development of blow molding machines, blow molding technology gained widespread application. Hollow containers with volumes of several thousand liters are now being produced using computer control. Plastic materials suitable for blow molding include polyethylene, polyvinyl chloride, polypropylene, and polyester. The hollow containers produced through blow molding are widely used as industrial packaging containers.

Blow molding can be divided into extrusion blow molding and injection blow molding, with new developments including multilayer blow molding and stretch blow molding.

The extrusion process involves extruding the plastic material, which has been melted, through a screw into an extrusion blow mold. The mold is then closed, and the product is formed by combining it with the following mold and compressed gas. The extrusion blow molding process consists of five steps:

- The melted raw material is formed into a plastic parison.

- The mold is closed to capture and separate a portion of the parison.

- Gas is injected into the mold cavity to shape the parison, followed by cooling.

- The mold is opened, and the formed container is taken out.

- Trimming the flash to obtain the final product.

- Process

- Preheating

The bottle preform is heated and softened by infrared high-temperature lamps, with the body of the preform being heated while the neck of the preform remains cool. A cooling device is used to cool the neck of the preform and maintain its shape.

4.Bottle Blowing

In this stage, the preheated bottle preform is placed in the prepared blow mold, and high-pressure air is blown into it to stretch and shape the preform into the desired bottle shape.

Bottle blowing machines on the market are generally divided into two types: fully automatic and semi-automatic.

Fully Automatic Blow Molding Machine the two operations of bottle preheating and mold insertion through the operation of a mechanical arm, eliminating the manual process of placing the preheated bottle preform into the mold. This greatly increases production speed but comes at a higher price compared to semi-automatic machines.

5.Product Selection

Choosing the right model of blow molding machine that meets your needs is a topic of great concern. Generally, the selection of the blow molding machine model is based on the desired product. Manufacturers with different production volumes typically focus on the number of cavities, bottle capacity, and hourly output.

Common types of blow molding machines include Automatic Blow Molding Machine, 5 Gallon Bottle Blow Molding Machine, PET Bottle Blowing Machine, and Rotary Blow Molding Machine. It is crucial to select the model that suits your needs based on your specific requirements.

6.Operational Steps

Step 1: Place the preform in the preform container, which is automatically transferred to the preform positioning device through a conveyor.

Step 2: The preform, with its neck facing upward, is automatically loaded onto the preform holder and then sent into the heating tunnel.

Step 3: After heating, the preform is transferred to the blow-stretch platform, where the mold is locked. The preform undergoes low-pressure blowing, high-pressure blowing, venting, and finally, the mold is opened.

Step 4: The formed bottle is taken off the blow-stretch platform by the automatic demolding system.

7.Technological Development

Beverage companies have two urgent needs for blow molding equipment. Firstly, due to the continuous increase in the price of plastic raw materials, beverage companies are constantly seeking ways to reduce packaging costs to maximize profits. Therefore, they need to use advanced blow molding equipment to produce lighter bottles. Secondly, with the rapidly changing market, beverage production companies must respond flexibly to the increasingly shorter lifespan of beverages. Correspondingly, there is a growing need for frequent product updates in PET bottle production, and the time required to change molds during the production process needs to be minimized. These two urgent needs pose a significant challenge to blow molding equipment suppliers.

Closed-loop technology refers to the integration of process parameters for line verification into the process control system of the stretch blow molding machine, forming a closed, automatic control, and automatic adjustment production cycle. Intelligent machine control technology aims to improve the quality assurance system of blow molding machines. The use of the AgrPETWallplus monitoring system allows for monitoring various data of the bottle preform, such as wall thickness. During operation, any data deviating from the system's set values will be immediately identified, and this information will be promptly transmitted to the control system of the bottle preform heating unit. The control system will quickly respond and independently control the set values of each heating lamp inside the heating furnace. Therefore, even though the data for each bottle may be different, the quality of the produced bottles remains stable and reliable as long as the initial process parameters are unchanged.

8.Maintenance

1.No material feeding: Several situations need to be checked:

-

- Is the material hopper empty? If so, it needs to be refilled promptly.

- If not, check if the control contactor of the elevator is powered. If it is powered, check if the motor is receiving power and under load. This situation is likely caused by the bottle preform getting stuck on the conveyor belt, and the simplest solution is to manually assist the lifting.

- If the control contactor of the elevator is not powered, check if the bottle preform detection photoelectric eye is not aligned with the reflector.

2.Material feed tray jammed: This is a more troublesome issue. Based on experience, it is less common when the length and weight of the bottle preform are larger.

3.Unable to extract the blown bottle from the mold:

-

- First, open the mold and manually perform the mold opening and closing. If it works fine, run it in empty mode.

- Check the exhaust time setting. If the exhaust setting is correct and the machine malfunctions every time a bottle is blown, it may indicate a problem with the exhaust valve. Open the exhaust valve and check the condition of the spring and seals (another symptom of this issue may be loud exhaust noises or incomplete exhaust).

- If many molds in production occasionally have difficulty opening, check if there are broken screws inside the locking mechanism. Also, check if the locking force is too high. If it is too high, it should be readjusted according to the standards.

4.Bottles frequently getting pinched: Check if the position of the mechanical arm is misaligned.

5.Collision between two mechanical arms: In this case, manually reset the mechanical arm. It is caused by misalignment.

9.Operating Guidelines

Essential knowledge for safe operation of fully automatic blow molding machines:

- Before starting each shift, lubricate all moving parts with oil (mechanical arm, mechanical arm rails, mold opening and closing rails).

- Grease the swing arm every 3-4 days. The large and small chains of the heating machine should be greased once a month. Regularly check if the main machine and heating machine reducers are adequately lubricated. Grease the main machine bearings every 3 months.

- Before production, check if all moving parts are secure, and if there are any loose or missing screws, especially in areas with strong impact. Check if the belt transmission is abnormal.

- Check if the high-pressure air source, low-pressure air source, power supply, and water supply are normal.

- Check if all emergency stop switches, safety door switches, and protective device detection switches are functioning properly.

- Check if the preform insertion and preform dropping processes of the heating head are functioning properly. If the preform is not in place, adjust the pressure of the preform device nut.

- Check if the light tubes are damaged or broken. Replace them promptly.

- Check if there is any air leakage in the pneumatic components and if the actions are sensitive.

- Check if the triple union has any abnormal air leakage, blockage, or if the water cup reservoir is too full.

- When an abnormality occurs in the solenoid valve of the fully automatic blow molding machine, it should be cleaned in a timely manner (clean it once every 3.5 million bottle blows).

10.Operating Principles of Blow Molding Machines

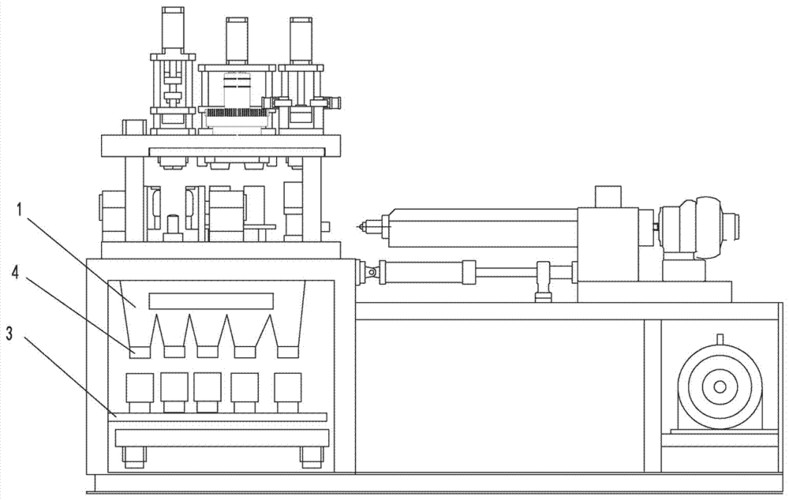

Blow molding machines can be mainly divided into three types: extrusion blow molding machines, injection blow molding machines, and special-structure blow molding machines. The processing techniques mainly include one-step and two-step methods. Both one-step and two-step methods are used for the formation of PET and BOPP hollow containers, each with its own characteristics and wide applications. Comparatively, the two-step method is more suitable for centralized production of preforms and decentralized blowing of bottles, while the one-step method equipment is more suitable for online production in beverage companies.

The blow molding process of the machine mainly consists of six steps:

- Place the heated plastic preform into the mold.

- Use the mold-locking cylinder to secure the mold.

- Apply high pressure or mechanical structures to lock the preform mold.

- Pre-blow the preform with medium to high pressure while stretching the cylinder to expand the preform mold.

- Perform high-pressure blowing to shape the bottle preform according to the mold and maintain pressure for a certain time.

- Release the high pressure in the formed bottle, reset the cylinder, and remove the bottle.

Pneumatic equipment plays a significant role in the operation of blow molding machines. From material feeding, mold locking, stretching, high-pressure blowing, air release to bottle removal, this series of actions are assisted by pneumatic equipment. For example, the stretching and high-pressure blowing air release circuits are divided into constant pressure and high-pressure sections.

HZM Machinery is a professional manufacturer of blow molding machines. We warmly welcome you to get in touch with us at any time. Whether you are interested in the price of a single machine or looking for a complete production line solution, we are here to assist you. Rest assured that all our equipment is offered at factory-direct prices.

TAG: Automatic Blow Molding Machine Blow Molding Machine

Bottled Water Production Line Equipment Prices And Parameters

Optimized Production Process for Plastic Extrusion Blow Molding Machine

Maintenance and Care Guidelines for Bottle Blowing Machine: 21 Tips

Delving into the Working Principles and Selection of Blow Molding Machines

From Manual to Automatic: Energy-Efficient PET Blow Molding for China

Blow Moulding machine Manufacturer Price

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine