-

![Industrial RO Drinking Water Treatment Plant – Reverse Osmosis Equipment for Beverage & Bottled Water]() Industrial RO Drinking Water Treatment Plant – Reverse Osmosis Equipment for Beverage & Bottled Water

Industrial RO Drinking Water Treatment Plant – Reverse Osmosis Equipment for Beverage & Bottled Water -

![bottled water treatment plant – water purification system for bottling line]() bottled water treatment plant – water purification system for bottling line

bottled water treatment plant – water purification system for bottling line -

![Industrial food water treatment equipment – 10T/H RO Water Treatment System]() Industrial food water treatment equipment – 10T/H RO Water Treatment System

Industrial food water treatment equipment – 10T/H RO Water Treatment System -

![Well Water Purification Small Ro System Ro Plant]() Well Water Purification Small Ro System Ro Plant

Well Water Purification Small Ro System Ro Plant -

![reverse osmosis water treatment]() reverse osmosis water treatment

reverse osmosis water treatment -

![Water Softener Filter System]() Water Softener Filter System

Water Softener Filter System -

![Water Treatment System]() Water Treatment System

Water Treatment System -

![RO Water Treatment System Drinking Water Purifier]() RO Water Treatment System Drinking Water Purifier

RO Water Treatment System Drinking Water Purifier

-

![Automatic Rotary Blow Molding Machine]() Automatic Rotary Blow Molding Machine

Automatic Rotary Blow Molding Machine -

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![PET Bottle Blow Molding Machine]() PET Bottle Blow Molding Machine

PET Bottle Blow Molding Machine -

![Plastic Bottle Blowing Machine, making machine]() Plastic Bottle Blowing Machine, making machine

Plastic Bottle Blowing Machine, making machine -

![Automatic Water Bottle Blowing Molding Machine]() Automatic Water Bottle Blowing Molding Machine

Automatic Water Bottle Blowing Molding Machine -

![5 Gallon Bottle Blow Molding Machine]() 5 Gallon Bottle Blow Molding Machine

5 Gallon Bottle Blow Molding Machine -

![Automatic PET Stretch Blow Molding Machine]() Automatic PET Stretch Blow Molding Machine

Automatic PET Stretch Blow Molding Machine -

![Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine]() Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine

Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine

-

![Glass Bottle CSD & Water Drinks Filling Machine]() Glass Bottle CSD & Water Drinks Filling Machine

Glass Bottle CSD & Water Drinks Filling Machine -

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]() Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer -

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]() PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine -

![Automotive Lubricants Oil Filling Machine]() Automotive Lubricants Oil Filling Machine

Automotive Lubricants Oil Filling Machine -

![Edible Oil Filling Machine]() Edible Oil Filling Machine

Edible Oil Filling Machine -

![Automatic Cooking Oil Filling Machine]() Automatic Cooking Oil Filling Machine

Automatic Cooking Oil Filling Machine -

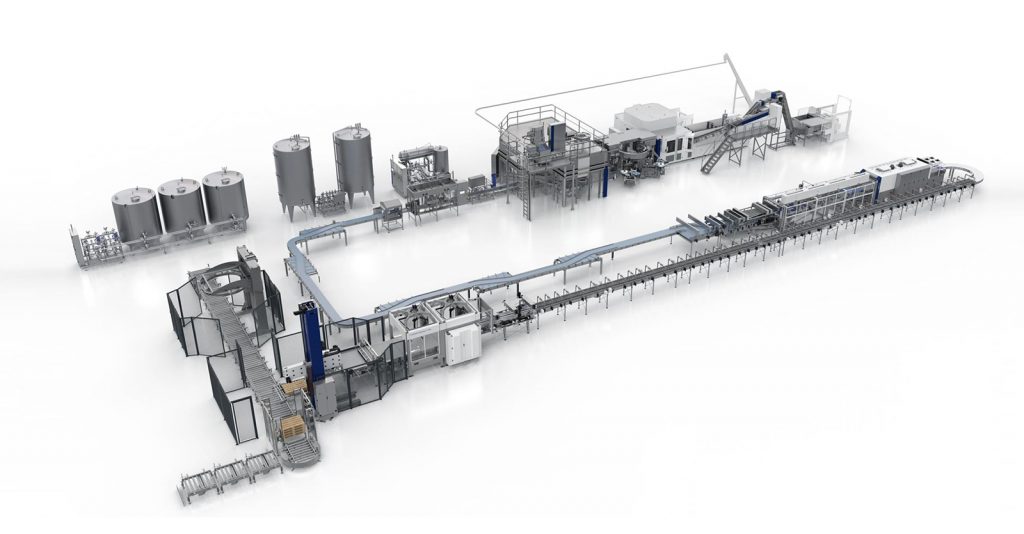

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine]() Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine

Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine -

![Automatic Water Bottle Labeling Machine]() Automatic Water Bottle Labeling Machine

Automatic Water Bottle Labeling Machine -

![Automatic rotary OPP labeling machine: Bottle labeling machine]() Automatic rotary OPP labeling machine: Bottle labeling machine

Automatic rotary OPP labeling machine: Bottle labeling machine -

![Automatic BOPP labeling machine]() Automatic BOPP labeling machine

Automatic BOPP labeling machine -

![Automatic High Speed Bottle Body Sleeve Labelling Machine]() Automatic High Speed Bottle Body Sleeve Labelling Machine

Automatic High Speed Bottle Body Sleeve Labelling Machine -

![Automatic Sleeve Labeling Machine]() Automatic Sleeve Labeling Machine

Automatic Sleeve Labeling Machine -

![Automatic Cold Glue Stick Labeling Machine]() Automatic Cold Glue Stick Labeling Machine

Automatic Cold Glue Stick Labeling Machine -

![Automatic Linear Type Adhesive Sticker Labeling Machine]() Automatic Linear Type Adhesive Sticker Labeling Machine

Automatic Linear Type Adhesive Sticker Labeling Machine