Beer Filling Machine Principle

Working Principle of Beer Filling Machine

The beer filling process is well-established and can be divided into seven basic parts. The filling machine is designed around the filling process, and its working principle involves the following steps:

- Clean bottles coming out of the bottle washer are transported to the filling machine by a bottle conveyor and enter the bottle screw, then move through the bottle starwheel to the bottle-holding cylinder on the rotary table, where they are elevated. The bottle neck is tightly pressed against the filling valve outlet by a positioning device, creating a seal.

- After the bottle is vacuumed, the backpressure gas (CO2) in the storage cylinder is injected into the bottle. When the gas pressure inside the bottle matches the pressure in the storage cylinder, the liquid valve opens due to the action of the valve spring. At this point, beer is guided into the glass bottle along the bottle wall through the action of the umbrella-shaped deflector on the return air pipe. CO2 in the glass bottle is exchanged back to the storage cylinder through the return air pipe.

- When the liquid rises to a certain height and seals the outlet of the return air pipe, it automatically stops filling. The liquid valve and gas valve are then closed to release the pressure gas in the bottle neck area to prevent foaming when the beer descends into the glass bottle. This completes the entire filling process.

- Classification and Selection of Liquid Filling Machines 2.1 Classification of Liquid Filling Machines Liquid filling machines can be classified based on the filling principle into atmospheric pressure filling machines, pressure filling machines, and vacuum filling machines.

- Atmospheric pressure filling machines rely on the weight of the liquid to fill containers under atmospheric pressure. These can be further categorized into timed filling and volumetric filling, suitable for low-viscosity, non-gaseous liquids like milk and wine.

- Pressure filling machines operate at pressures higher than atmospheric pressure. They can be divided into two types: isobaric filling, where the pressure in the storage tank matches that in the bottle, allowing liquid to flow by gravity, and overpressure filling, where the pressure in the storage tank is higher, and the liquid is forced into the bottle. These are suitable for filling carbonated liquids like beer, soda, and champagne.

- Vacuum filling machines fill containers at pressures lower than atmospheric pressure. They are versatile and suitable for various liquid viscosities, including oils, syrups, and fruit juices.

Selection of Liquid Filling Machines When selecting a filling machine, several factors should be considered:

- The nature of the filling material (viscosity, foaming, volatility, gas content, etc.) should match the appropriate filling machine to meet production requirements.

- The production capacity of the filling machine should match the capacities of preceding and subsequent processing and packaging machinery.

- High productivity and good product quality are crucial. High productivity improves economic efficiency, but it's essential to balance it with equipment precision and automation level.

- A wide process range is desirable to accommodate various production needs in the beverage industry.

- Consider the cost, ease of maintenance, size, and weight of the filling machine.

- Basic Filling Methods Filling methods vary depending on the physical and chemical properties of the liquid. Common filling methods include atmospheric pressure filling, isobaric filling, vacuum filling, siphon filling, and pressure filling, each suited to specific types of liquids and production requirements.

- Filling Cap Sealing Methods Filling and capping machines integrate mechanical structures with modern automated control technologies such as PLC programming, variable frequency speed control, and human-machine interfaces. When the system operates normally, it runs automatically, coordinating actions such as bottle feeding, filling, capping, and safety protection based on the presence or absence of bottles and predetermined speeds. The monitoring function of the control system checks the system's status, bottle feeding, and bottle breakage detection switches by detecting the position of small iron pieces on each part above the bottle-pressing section, generating photoelectric pulses. In the event of misjudgment, adjustments must be made to correct the position of the detection switch and small iron pieces. This method is outdated and may not provide immediate feedback.

To address these issues, a new detection function has been added in the form of a touch screen interface, allowing real-time monitoring of the bottle positions, bottle breakage, and switch states, greatly improving system reliability and user-friendliness.

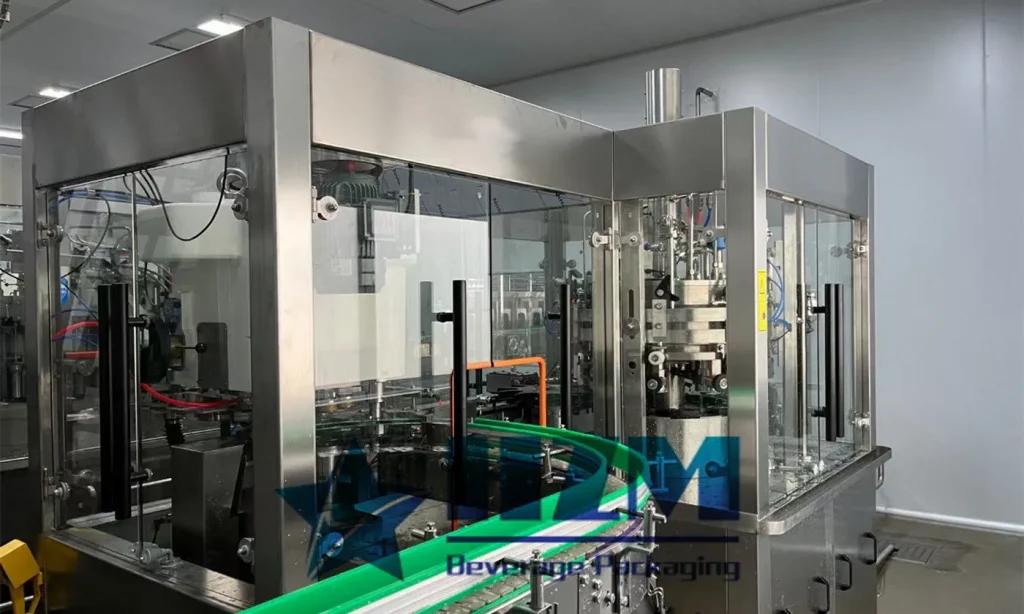

- Design of a Rotary Beer Filling Machine The design of a rotary beer filling machine involves several key steps:

- Bottle Feeding: Empty bottles are transported to the rotary table using a conveyor belt.

- Filling: Liquid is pumped into the bottles using filling pumps positioned above specific workstations.

- Capping: Caps are sealed onto the bottles through a stamping process, mainly using a linkage structure.

- Output: The filled and capped containers are moved along a conveyor belt for packaging.

The focus of the design is on the intermittent movement of the turntable, the stamping process during sealing, and the positioning of the workpieces, along with the selection and design of mechanisms for these actions.

Considering the advantages and disadvantages of different mechanisms, the final design incorporates the following elements:

- The intermittent movement of the turntable is achieved through an incomplete gear mechanism.

- The sealing process is carried out using a linkage mechanism.

- The workpiece positioning mechanism employs a cam mechanism.

This design provides a balanced solution for the rotary beer filling machine, ensuring smooth and efficient operation.

TAG: Beer Filling Machine filling machines

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?