Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling Machines

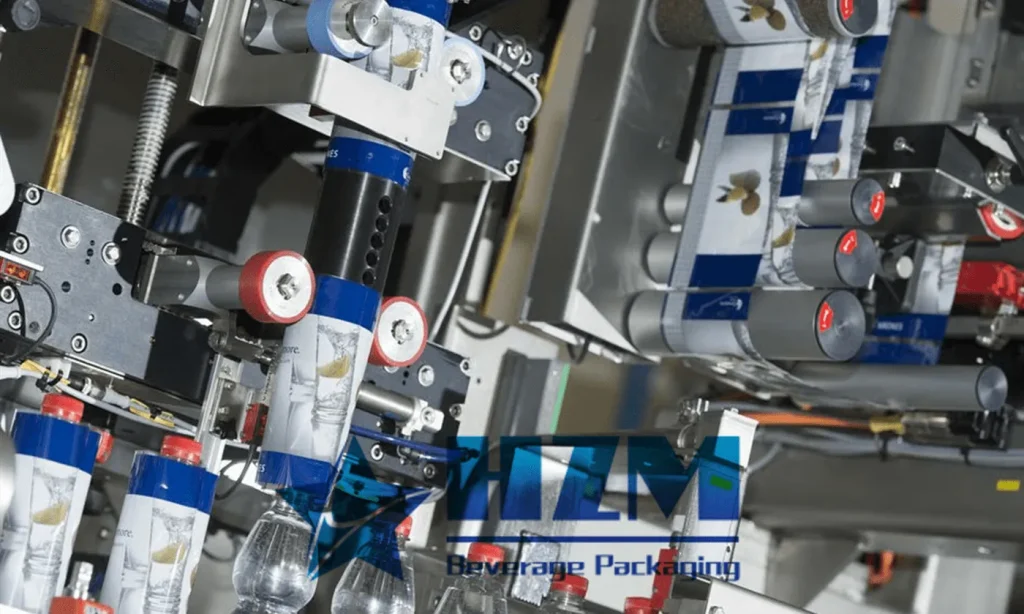

Sleeve Labeling Machine is a widely used equipment in the packaging industry, designed to attach plastic or paper labels onto various containers. It enables efficient labeling processes on production lines, enhancing packaging efficiency and quality. This article will provide information on the direct manufacturer's prices, HZM manufacturer, functions, applicable industries, detailed specifications, procurement considerations, and maintenance tips for Sleeve Labeling Machine.

The direct manufacturer's prices of Sleeve Labeling Machine may vary based on different models and configurations. Generally, detailed quotations and purchasing information can be obtained by directly contacting the manufacturer or authorized distributors. Factors such as equipment quality, performance, and after-sales services should be considered when making a purchase, ensuring the selection of a reliable manufacturer and suitable model.

HZM is a manufacturer with extensive experience and a good reputation in the field of Sleeve Labeling Machine. They are committed to providing high-quality labeling equipment to meet customer needs. By choosing products from HZM manufacturer, you can expect reliable equipment performance and professional after-sales support.

The main function of the Sleeve Labeling Machine is to attach labels to containers of various shapes, such as bottles, cans, and drums. It can be applied to multiple industries including food and beverages, cosmetics, pharmaceuticals, personal care products, and more. By using a Sleeve Labeling Machine, companies can add identification, branding information, and product descriptions to their packaging, enhancing market competitiveness and brand image.

Here are some detailed specifications of Sleeve Labeling Machine:

- Applicable label materials: plastic films, shrink films, etc.

- Applicable container size range: diameter (20mm-200mm), height (30mm-400mm)

- Production speed: Varies depending on the equipment model and configuration, generally ranging from 100 to 600 bottles per minute.

- Power supply voltage: Varies depending on the equipment model and configuration, typically 220V/50Hz or 380V/50Hz.

- Equipment dimensions: Varies depending on the equipment model and configuration, with specific dimensions customizable according to requirements.

When purchasing a Sleeve Labeling Machine, attention should be paid to the following aspects:

- Equipment quality and performance: Choose well-known brands or manufacturers with a good reputation to ensure reliable equipment quality and stable performance.

- Equipment suitability: Select the appropriate equipment model and configuration based on your product characteristics and production needs.

- After-sales service: Understand the manufacturer's after-sales service policies and commitments to ensure timely access to maintenance and technical support.

- Price and cost-effectiveness: Consider the price, performance, and quality of the equipment comprehensively, choosing a product with good cost-effectiveness.

To maintain the proper functioning and extend the lifespan of the Sleeve Labeling Machine, here are some maintenance tips:

- Regularly clean the equipment to prevent dust and impurities from causing damage.

- Lubricate moving parts and bearings regularly to ensure smooth operation.

- Inspect electrical components periodically, including wiring, switches, sensors, etc., to ensure reliable electrical connections.

- Conduct regular inspections and adjustments to tighten loose parts and perform necessary replacements when needed.

By providing information on the direct manufacturer's prices, HZM manufacturer, functions, applicable industries, detailed specifications, procurement considerations, and maintenance tips for Sleeve Labeling Machine, we hope to assist you in gaining a better understanding and making informed choices regarding the labeling equipment that suits your needs. During the purchasing and operating process, it is advisable to engage in thorough communication and discussions with manufacturers or professionals to ensure accuracy and effectiveness in selection and operation.

What Machines Are Used to Apply Plastic Labels on Beverage Bottles?

Automatic 150BPM Sleeve Shrink Labeling Machine

Automatic Water Bottle Sleeve Labeling Machine

User Guide for Automatic Sleeve Labeling Machine

A Reliable Manufacturer of Automatic Sleeve Labeling Machines

Applications of Automatic Sleeve Labeling Machines in Various Industries

Pricing Guide for Automatic Sleeve Labeling Machines: HZM Machinery Direct Sales Prices

A Guide to Avoid Pitfalls When Purchasing an Automatic Sleeve Labeling Machine

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine