Raw Water Treatment System for Beverage Plant

A reliable raw water treatment system is the foundation of any beverage production line. Whether producing bottled water, carbonated drinks, juice, or functional beverages, the quality of raw water directly affects product taste, safety, equipment lifespan, and regulatory compliance.

As a professional beverage packaging equipment manufacturer, HZM Machinery provides integrated water treatment systems tailored for complete beverage production lines, ensuring stable water quality from raw source to filling.

Why Raw Water Treatment Is Critical in Beverage Plants

Raw water sources such as groundwater, surface water, or municipal supply often contain:

-

Suspended solids and turbidity

-

Dissolved salts and hardness

-

Microorganisms (bacteria, algae)

-

Organic matter and odor

-

Heavy metals or residual chlorine

Without proper treatment, these impurities can lead to:

-

Inconsistent beverage taste

-

Product safety risks

-

Scaling and corrosion of filling equipment

-

Higher maintenance costs and downtime

A well-designed raw water treatment system ensures consistent, food-grade water quality before it enters the beverage processing stage.

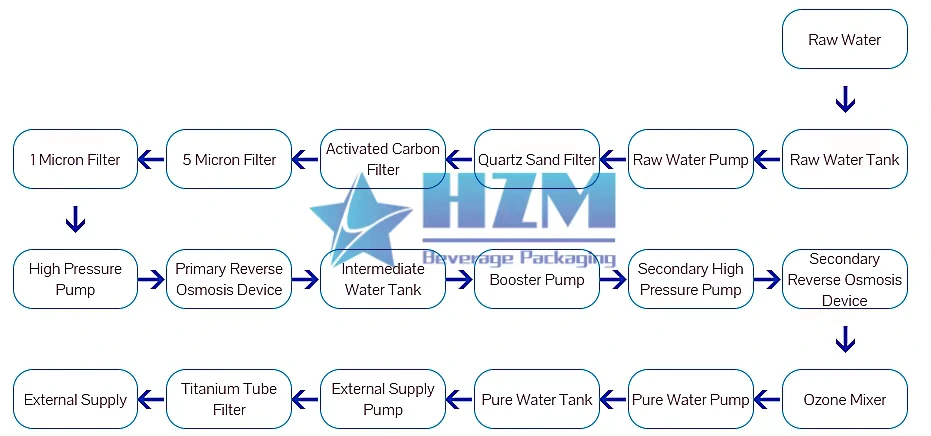

Typical Process of a Raw Water Treatment System

Based on practical project experience in beverage plants, a standard system usually includes the following stages:

1. Pre-treatment (Physical Filtration)

-

Multi-media sand filter

-

Activated carbon filter

Purpose:

Remove suspended solids, turbidity, odor, and residual chlorine, protecting downstream equipment.

2. Softening or Desalination (Optional)

-

Water softener or reverse osmosis (RO) system

Purpose:

Reduce hardness and dissolved salts, especially important for bottled water and sensitive beverage formulations.

3. Fine Filtration

-

Precision cartridge filters (1–5 micron)

Purpose:

Ensure stable water clarity before sterilization.

4. Sterilization

-

UV sterilizer and/or ozone system

Purpose:

Eliminate microorganisms without affecting taste or chemical composition.

In high-capacity beverage plants, HZM Machinery often recommends UV + ozone dual sterilization for higher safety redundancy.

System Design Based on Beverage Type

Different beverages require different water quality standards:

-

Bottled water: Strict mineral and microbial control

-

Carbonated drinks: Stable TDS and low organic content

-

Juice & tea beverages: Clean, neutral water to avoid flavor interference

HZM Machinery designs water treatment systems based on actual product requirements, not a one-size-fits-all configuration.

Practical Experience from Beverage Production Lines

From real production line projects, we have found:

-

Over-designed systems increase investment without improving product quality

-

Under-designed systems cause frequent filter replacement and unstable output

-

Water treatment must match filling capacity (BPH), not just water source

For example, in a 12,000 BPH bottled beverage line, improper RO sizing can cause pressure fluctuations, directly affecting filling accuracy.

Why Choose HZM Machinery

HZM Machinery is a professional beverage packaging equipment company, providing:

-

Complete beverage production lines

-

Customized raw water treatment systems

-

Integration with filling, capping, and packaging equipment

Our advantages:

-

System design based on real production experience

-

Equipment optimized for long-term stable operation

-

One-stop solution from water treatment to final packaging

By integrating water treatment systems into the overall beverage line, HZM Machinery helps beverage manufacturers achieve stable quality, lower operating costs, and reliable production efficiency.

Conclusion

A professional raw water treatment system is not just an accessory, but a core part of beverage production. Proper system design ensures product safety, consistent taste, and long-term equipment performance.

With proven experience in beverage production lines, HZM Machinery provides reliable water treatment solutions tailored for beverage plants worldwide.

-

![Raw Water Treatment System for Beverage Plant]()

Raw Water Treatment System for Beverage Plant

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line