Why Do Automatic Edible Oil Filling Machines Experience Oil Leakage?

Many edible oil manufacturers, in pursuit of increased efficiency and production output, opt to equip their production lines with automatic edible oil filling machines. However, one of the primary concerns for these manufacturers is the occurrence of oil leakage in automatic edible oil filling machines. When such a situation arises, it not only disrupts regular production but also results in wastage of edible oil. Today, let's delve into the reasons behind the occurrence of oil leakage in automatic edible oil filling machines.

As China's manufacturing capabilities have significantly improved, automatic edible oil filling and packaging equipment have witnessed substantial advancements in performance, appearance, functionality, and configuration. Currently, the primary cause of oil leakage in automatic edible oil filling machines is typically attributed to improper equipment usage.

So, what measures should be taken when an issue arises with an edible oil filling machine?

Given that edible oil is a viscous liquid, rapid filling during the filling process can easily generate air bubbles, leading to oil overflow. To address this issue, it is advisable to consider reducing the filling speed.

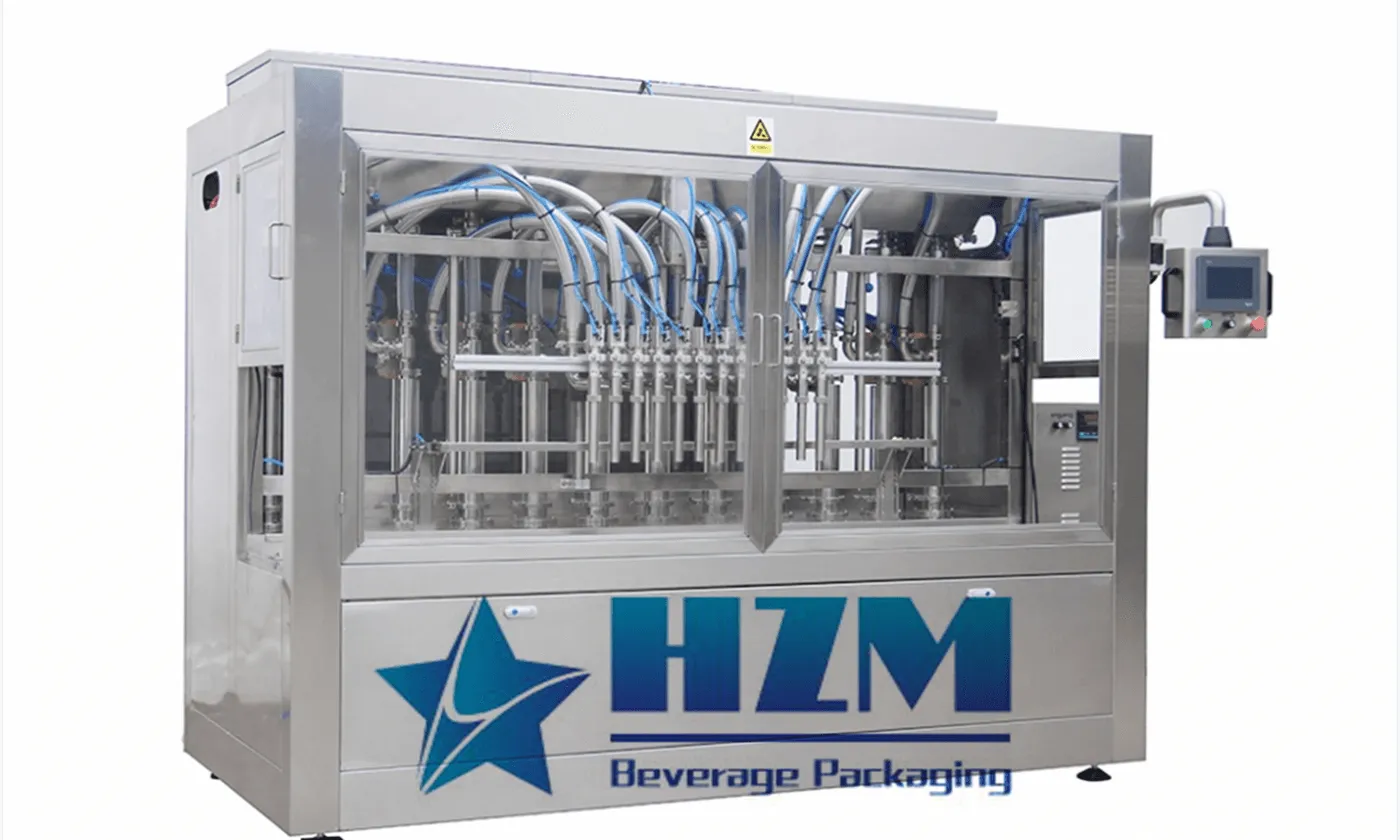

HZM's automatic edible oil filling machines are equipped with a PLC system, allowing for easy adjustment of filling speed and specifications, thus effectively resolving the problem of oil overflow.

TAG: Edible Oil Filling Machine Linear Type Oil Filling Machine

PREVIOUS : Olive Oil Filling Machine

Analysis of Reasons for Inaccurate Counting of Flowmeter in Edible Oil Filling Machine

Manufacturer of edible oil filling machines offers stable and user-friendly equipment

Introduction to the Edible Oil Filling Production Line

Edible Oil Production Line Equipment and Costs

Choosing Quality Cooking Oil: Tips from Edible Oil Filling Machine Manufacturer

The Trend Towards Automation and Intelligence in Edible Oil Filling Machines

Addressing the Leakage Problem of the Edible Oil Filling Machine’s Filling Head

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine