Bottled drinking water on the market comes in various packaging forms, including small bottles (e.g., 500ml), large bottles (1~5L), and 5-gallon water containers. Small bottles dominate the market due to their portability and convenience. Both large and small bottles are easy to transport, while 5-gallon containers are suitable for local sales but inconvenient for transportation. Particularly in developed urban areas, awareness of healthy drinking water has been increasing, with 5L water becoming commonplace in households, even widely adopted in university dormitories as a replacement for traditional barrel water.

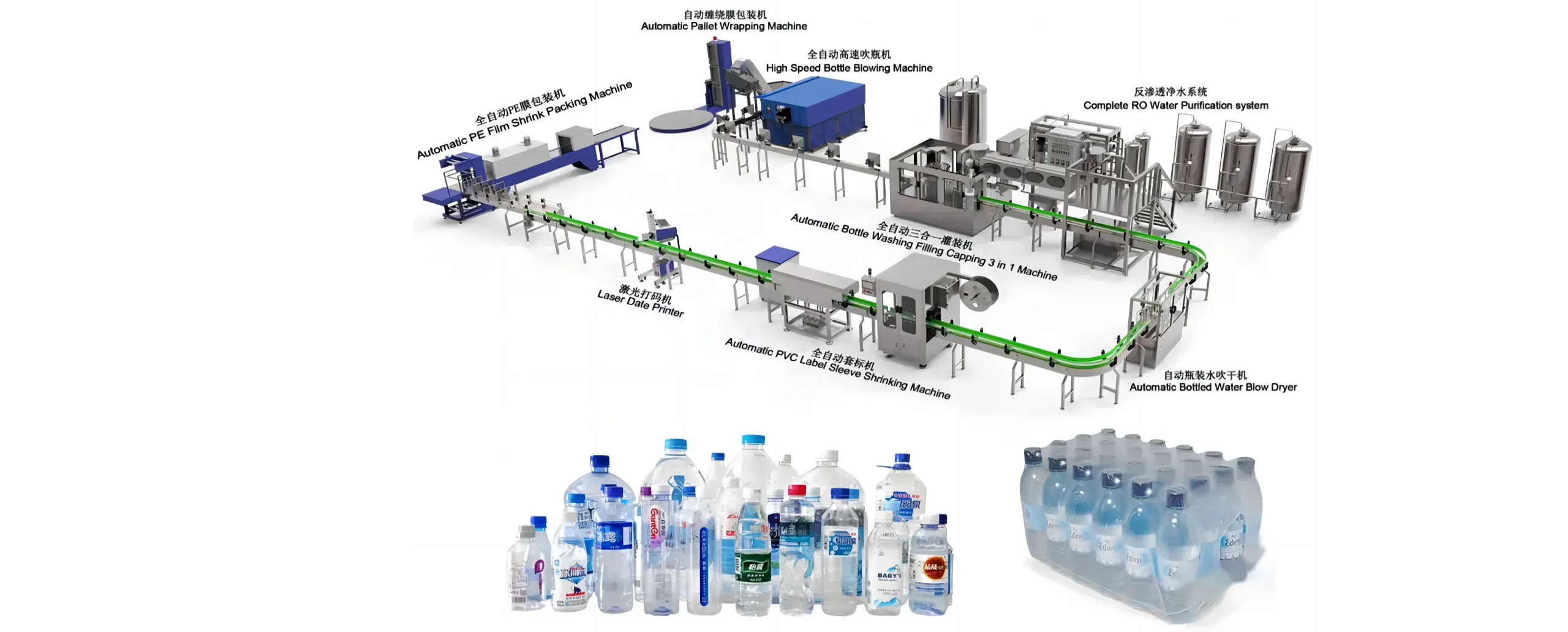

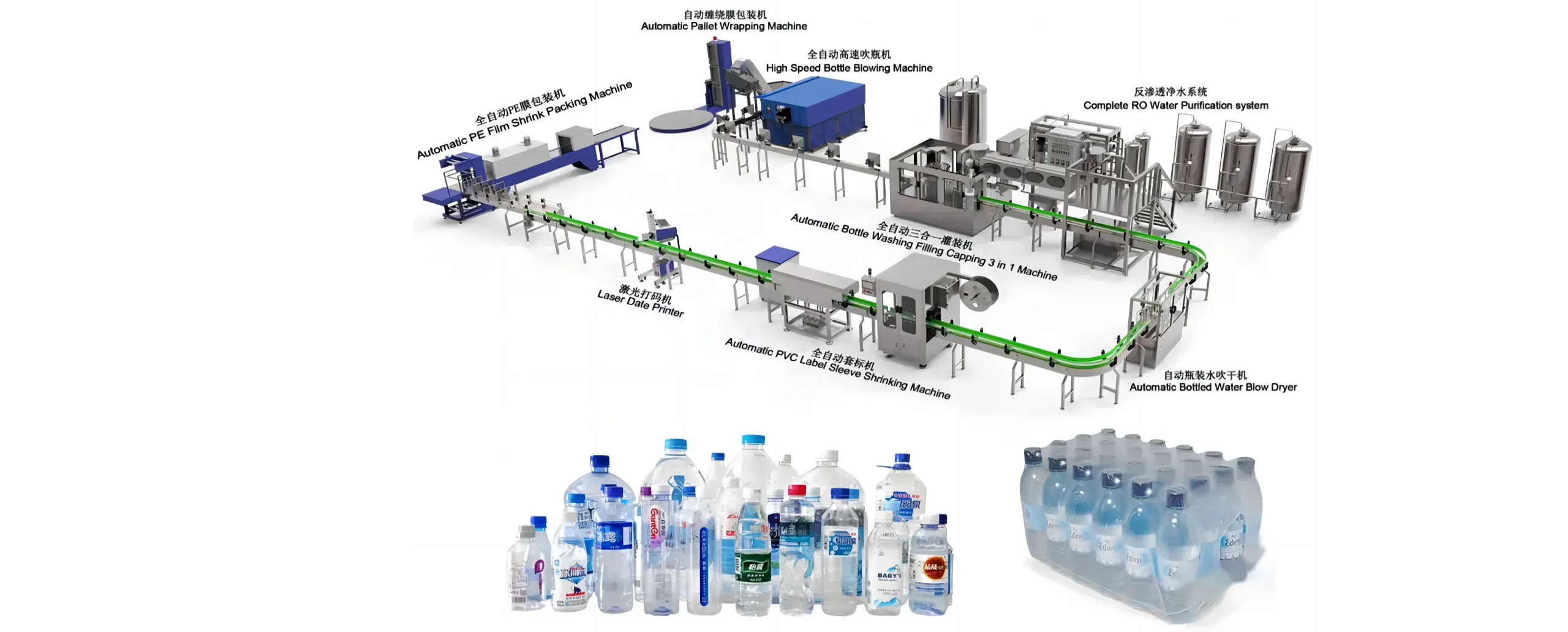

Today, we will delve into the equipment and production process of bottled drinking water production lines.

HZM Machinery is a comprehensive professional supplier of Bottled Drinking Water Production Lines, integrating R&D, manufacturing, and sales. We offer turnkey projects and have a team of professional after-sales service engineers. Currently, our equipment is exported to over 30 regions and countries in both domestic and international markets.

Now, let's provide a concise overview of the equipment constituting a fully automatic small-bottle mineral water production line. This information is intended for manufacturers looking to procure equipment for bottling mineral water. The production line includes:

Equipment Composition:

-

- Source water tank

- Boosting pump

- Quartz sand filter

- Activated carbon filter

- Precision filter

- Hollow fiber filter or nanofiltration equipment

- UV sterilizer

- Ozone generator

- Pure water tank

-

Bottle Blowing System:

- Automatic bottle blowing machine

- Automatic preform loading machine

- High-pressure air compressor

- Low-pressure air compressor

- High-pressure air storage tank

- Low-pressure air storage tank

- High-pressure air dryer

- Low-pressure air dryer

- Oil-water separator

- Water chiller

- Bottle molds

-

Filling System:

- Three-in-one atmospheric pressure filling equipment

- Automatic capping machine

- Online bottle cap disinfection equipment

-

Finished Product Handling System:

- Empty bottle air conveyor system

- Light inspection equipment

- Powerful air dryer

- Date coding machine

- Labeling equipment

-

Packaging Equipment:

- PE film heat shrink packaging machine

- Carton packaging machine

Production Process:

- Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse.

- Empty bottles are conveyed through an air duct to the three-in-one filling machine, undergoing high-pressure washing, filling, and capping. The washing water is the same as the filling water, utilizing gravity for the filling process.

- Capping involves screwing on caps using the same principle as daily bottle cap tightening.

- Caps undergo sterilization, with pre-sterilization using a cap disinfection cabinet employing UV light and ozone. This method involves some manual contact before capping, potentially introducing minimal contamination. Post-sterilization occurs in a tunnel between the capping and cap screwing units, ensuring a safer process, albeit at a higher equipment cost.

- Light inspection equipment emits white light, and 1-2 personnel rotate to visually check for impurities in bottled water.

- Laser coding is used for date coding, offering high equipment costs but low consumable expenses compared to inkjet coding.

- Labeling equipment includes options like sleeve labelers (e.g., used by Nongfu Spring and Wahaha) or hot melt adhesive labeling machines (e.g., used by Nongfu Spring and Hengda Ice Spring). The choice depends on the product's positioning.

- Final packaging equipment options include PE film heat shrink packaging for high-end products or carton packaging for lower-end products.

By following these steps, the smooth procurement, installation, and production of a bottled drinking water production line can be ensured, enhancing production efficiency and product quality.

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

![Glass Bottle CSD & Water Drinks Filling Machine]()

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()