Variable Frequency Speed Regulation MMI Juice Filling Machine

| Material: | Stainless Steel | Process: | Pressure Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Filling Valve: | Gravity Mechanical Valve Or Customer Needs | Applicable Bottle Type: | 200ml-1500ml |

| Application: | Juice Tea Drink | Function: | Juice Filling Machine |

| Model: | DGC15 | Number Of Bottle Rinsing Clip: | 50 |

| Number Of Filling Valve: | 50 | Number Of Capping Head: | 15 |

| Capacity: | 18000-20000 BPH | Bottle Diameter: | Φ60-Φ96 Mm |

| Bottle Height: | 180-315 Mm | Bottle Volume: | 350-1500 Mm |

| Outline Dimensions: | 5300x4200 X2900 Mm | Weight: | 10000 Kg |

| High Light: | MMI Juice Filling Machine, 200ml Juice Filling Machine, 200ml Juice Tea Drink Filling Machine | ||

Variable Frequency Speed Regulation MMI Juice Filling Machine

PLC MMI Variable Frequency Speed Regulation Juice Filling Machine

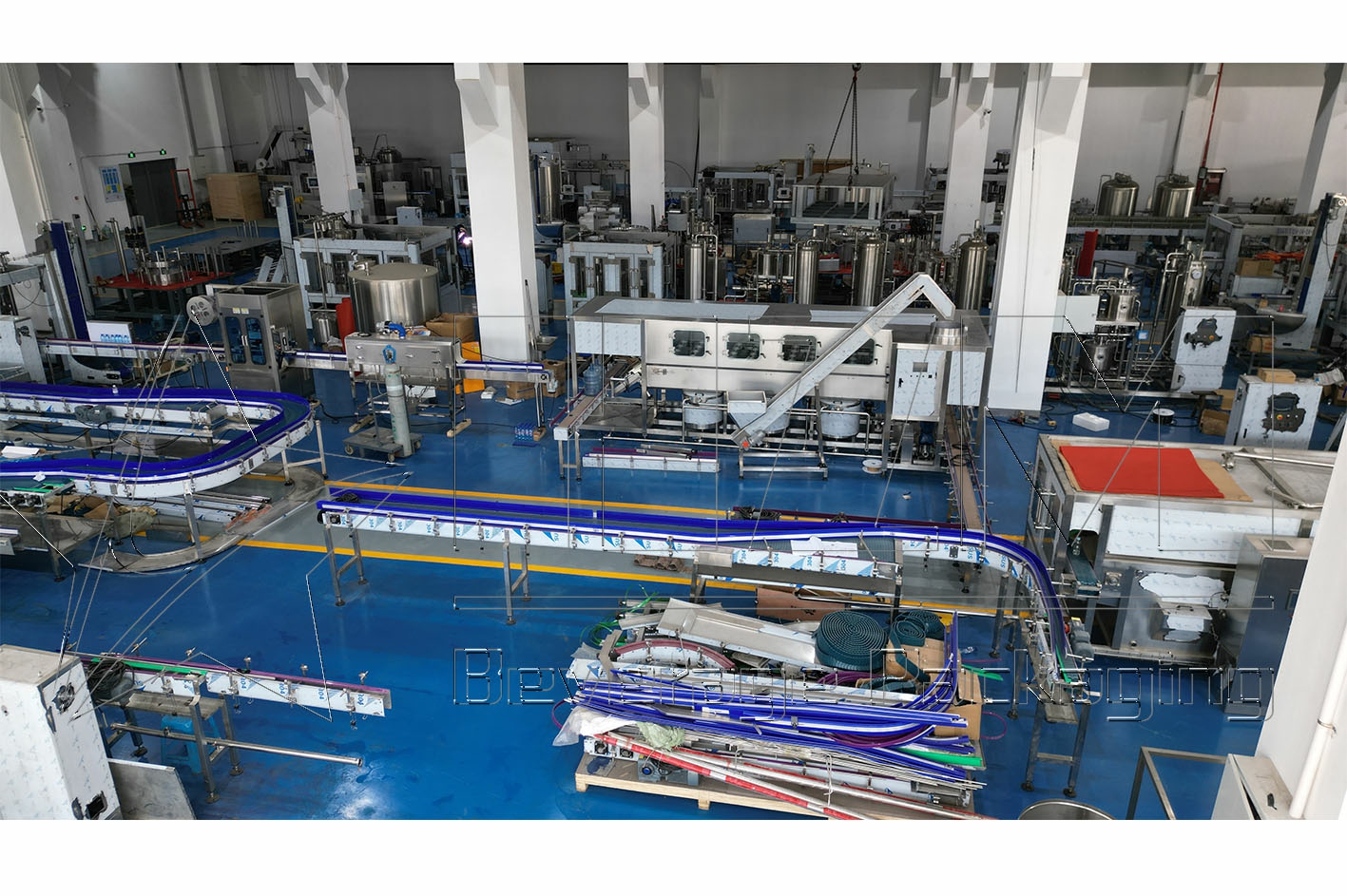

Our juice, tea drink production line is designed and built for filling juice and tea drink into PET bottles. Besides, it also can be used for filling non-carbonated liquid like water. The production capacity of this juice, tea drink production line ranges from 6000 to 24000 bottles/hour. This beverage production line adopts PLC, man-machine interface and frequency conversion, and is equipped with filling temperature control system and CIP cleaning system. Additionally, the utilization of low vacuum filling method makes this line meet the technical requirement of various kinds of juice and tea drink.

Fully enclosed combined trinity high temperature filling unit. The whole production line is controlled by PLC, MMI, variable frequency speed regulation, equipped with a filling temperature control system and CIP self-cleaning system, and a low vacuum filling method, which can fully meet the technical requirements of various juices and tea beverages.

Specifications of Bottled Water Filling Machine

| Model | Number of Bottle Rinsing Clip | Number of Filling Valve | Number of Capping Head | Capacity

(BPH) |

Bottle Size |

Outline Dimensions (mm) | Weight (Kg) | Remark | ||

| Diameter (mm) | Height (mm) | Volume (ml) | ||||||||

| DGC06 | 18 | 18 | 6 | 5000-6000 | Φ60-Φ96 | 180-315 | 350-1500 | 2480x1980x2600 | 4000 | All-in-one Type |

| DGC08 | 24 | 24 | 8 | 6000-10000 | Φ60-Φ96 | 180-315 | 350-1500 | 2800x2400 x2600 | 6000 | All-in-one Type |

| DGC10 | 32 | 32 | 10 | 10000-14000 | Φ60-Φ96 | 180-315 | 350-1500 | 3300x3000 x2700 | 7200 | All-in-one Type |

| DGC12 | 40 | 40 | 12 | 14000-18000 | Φ60-Φ96 | 180-315 | 350-1500 | 3900x3180 x2700 | 9000 | All-in-one Type |

| DGC15 | 50 | 50 | 15 | 18000-20000 | Φ60-Φ96 | 180-315 | 350-1500 | 5300x4200 x2900 | 10000 | All-in-one Type |

| DGC15 | 60 | 60 | 15 | 20000-24000 | Φ60-Φ96 | 180-315 | 350-1500 | 5700x4600 x2900 | 12000 | All-in-one Type |

| DGC18 | 72 | 72 | 18 | 22000-28000 | Φ60-Φ96 | 180-315 | 350-1500 | 6600x5100 x2900 | 15000 | All-in-one Type |

Features

In order to meet the related food hygiene requirements, all parts in contact with liquid are manufactured by quality stainless steel, for instance, the filling valves are made of stainless steel 316.

Adopting low vacuum pressure filling method, our juice, tea drink production line achieves high filling speed, high filling precision and great filling quality at the same time.

Bottles are fed by the air conveyor and transported by clipping the bottle neck and put out by normal conveyor chain. Hence, it is easy and convenient to change bottle size.

The use of "PICK, PLACE" capping system ensures reliable capping, the adoption of magnetic torque structure makes it convenient to adjust the torque.

HZM Packaging Machinery Co., Ltd. is a comprehensive liquid beverage packaging solution provider specializing in design, manufacturing, sales and service. It has been deeply involved in the packaging machinery industry for nearly 10 years. Its service areas are widely used in beverages , dairy products, and condiments. It is one of the manufacturers with the highest level of technology and the most complete varieties of equipment for the production of liquid beverages in many packaging industries in China, such as alcohol, daily chemicals.

TAG: 200ml Juice Filling Machine 200ml Juice Tea Drink Filling Machine Juice Filling Machine MMI Juice Filling Machine

-

![Raw Water Treatment System for Beverage Plant]()

Raw Water Treatment System for Beverage Plant

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line