Filling Machine Types Overview

What is a filling machine? A filling machine is a mechanical device used for filling substances into containers. It is a subcategory of packaging machinery, and based on the level of automation in production, it can be classified into semi-automatic filling machines and fully automatic filling production lines. From the perspective of packaging materials, filling machines can be further categorized into liquid filling machines, paste filling machines, powder filling machines, and granule filling machines.

Numerical Control Liquid Filling Machine

Equipment Features:

The YS-160 model numerical control liquid filling machine utilizes a microcomputer to control factors such as filling time and motor speed for a uniform and minimally error-prone liquid filling process. It is widely used in industries such as pharmaceuticals, chemicals, food and beverages, and cosmetics. It is suitable for low-viscosity liquids without particles, and is designed for small-batch production.

The pump body of the water pump is made of corrosion-resistant materials synthesized from various imports, and the pump body is separated from the motor. The pump body has five mechanical metal components with no wear and tear. It possesses qualities such as oil resistance, heat resistance, alkali resistance, corrosion resistance, and chemical resistance. This water pump combines the advantages of a self-priming pump and a chemical pump, featuring self-priming capability, thermal protection, stable operation, and the ability to run continuously for a long time under both no-load and continuous load conditions.

Technical Parameters:

Power Supply: AC180V-260V 30W

Filling Range: 5ml-3500ml

Filling Nozzle Diameter: 8mm

Maximum Flow Rate: 3.2L/min

Maximum Suction Lift: 2m

Repetition Error: <0.5%

Dimensions: 400×380×200 (mm)

Weight: 5.5kg

Double-Head Pneumatic Liquid Filling Machine

Technical Parameters:

Filling Heads: 2

Filling Speed: 20-60 bottles/min

Filling Accuracy: ≤±1%

Power Supply: 220V/110V 50/60Hz

Air Pressure: 0.4-0.6 MPa

Optional Models: 5-100, 10-280, 20-500, 100-1000ml

Product Introduction:

- Suitable for pharmaceuticals, daily chemicals, food, pesticides, and special industries, it is an ideal filling equipment for fluid foods, medicinal liquids, solutions, pesticides, perfumes, cosmetics, oils, and other liquids.

- This machine is a double-head semi-automatic piston-type pneumatic filling machine with a reasonable design, compact structure, and easy operation. The pneumatic components are all made of internationally advanced pneumatic elements.

- The parts of this quantitative filling machine that come into contact with materials are made of stainless steel, meeting GMP requirements.

- Filling volume and speed can be adjusted arbitrarily, with high filling accuracy.

- The filling nozzles are equipped with anti-drip, anti-drawing, and lifting filling devices.

- This filling machine can be modified into an explosion-proof and overflow filling system.

Horizontal Pneumatic Liquid Filling Machine

Equipment Introduction:

- This model of liquid filling machine is suitable for pharmaceuticals, daily chemicals, food, pesticides, and special industries, making it an ideal liquid filling device.

- The machine is a semi-automatic piston-type, also known as a plunger-type filling machine, with a reasonable design, compact structure, and easy operation.

- The parts that come into contact with materials are made of 304/316L stainless steel, meeting GMP requirements.

- Both filling volume and speed can be adjusted arbitrarily, ensuring high filling accuracy.

- This filling machine can be modified into a double-head or explosion-proof filling system.

- The main power source for this machine is compressed air, and customers need to provide their own air compressor equipment.

Technical Parameters:

Filling Speed: 0-25 bottles/min

Filling Accuracy: ≤±1% (actual value is approximately 0.5%)

Power Supply: 220V 50/60Hz

Air Pressure: 0.4-0.6 MPa

Optional Models: 5-100ml, 10-280ml, 20-500ml, 100-1000ml, 500-2000ml, 2000-5000ml

Dimensions: 1100×300×400mm (20-500ml model)

Weight: 30KG (20-500ml model)

Wearing Parts: Sealing Ring

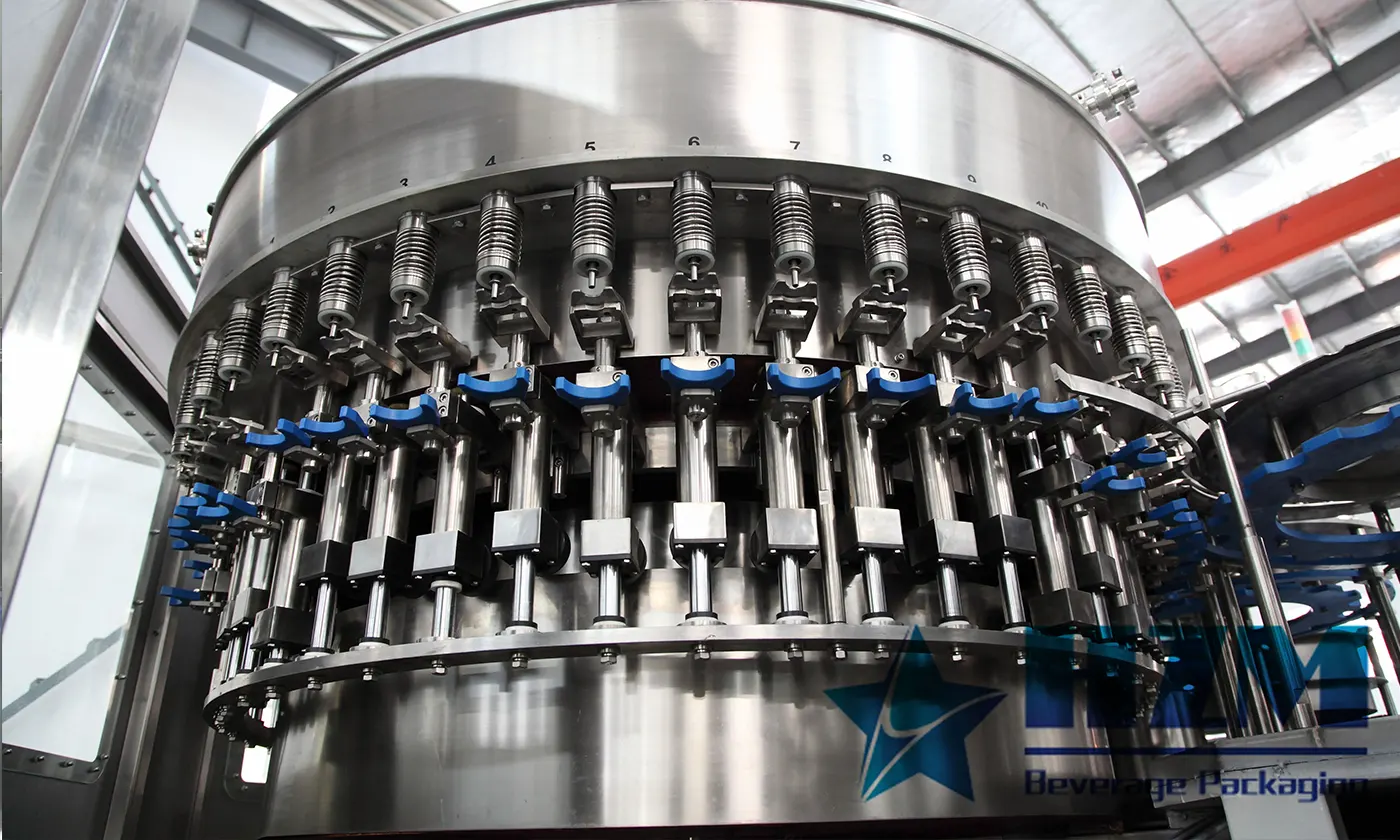

Rotary Liquor Filling Machine

Equipment Introduction:

This model of filling machine is suitable for filling non-particulate liquids such as mineral water, liquor, pesticides, chemical products, and food. It is used for liquid filling in various irregularly shaped bottles. The machine is characterized by its small size, light weight, easy operation, and simple maintenance.

Technical Parameters:

Production Efficiency: 2400 bottles/hour

Number of Filling Heads: 12 heads

Filling Volume: 150-800ml

Bottle Height: 60-320mm

Filling Accuracy: ±1%

Motor Power: 370W

Gear Pump Liquid Filling Machine

Equipment Introduction:

This machine adopts a new type of filling equipment that uses a self-priming pump to determine the filling volume based on the pump speed and working time. It is widely applicable to the filling of non-corrosive liquids such as beverages, liquor, cosmetics, spices, medicine, purified water, pesticides, and chemical products. The structure is simple, and operation is convenient. The discharge nozzle can be extended, and the flexible tube can be moved arbitrarily for filling, meeting the requirements of unlimited (adjustable) filling capacity of 5ml and above. It is a reliable and durable filling equipment.

Technical Parameters:

Motor Power: 20W

Filling Time: 0-99.99 seconds

Filling Volume: 5ml and above

Filling Speed: Adjustable

Optimal Filling Range: 5ml-1000ml

Dimensions: 345×285×135mm

Weight: 6KG

Numerical Control Liquid Filling Machine

Equipment Features:

numerical control liquid filling machine utilizes a microcomputer to control factors such as filling time and motor speed for a uniform and minimally error-prone liquid filling process. It is widely used in pharmaceuticals, chemicals, food, beverages, cosmetics, and other industries, suitable for low-viscosity liquids without particles, and is designed for small-batch production.

The pump body of the water pump is made of corrosion-resistant materials synthesized from various imports, and the pump body is separated from the motor. The pump body has five mechanical metal components with no wear and tear. It possesses qualities such as oil resistance, heat resistance, alkali resistance, corrosion resistance, and chemical resistance. This water pump combines the advantages of a self-priming pump and a chemical pump, featuring self-priming capability, thermal protection, stable operation, and the ability to run continuously for a long time under both no-load and continuous load conditions.

Technical Parameters:

Power Supply: AC180V-260V 30W

Filling Range: 5ml-3500ml

Filling Nozzle Diameter: 8mm

Maximum Flow Rate: 3.2L/min

Maximum Suction Lift: 2m

Repetition Error: <0.5%

Dimensions: 400×380×200 (mm)

Weight: 5.5kg

Electric Self-Priming Liquid Filling Machine

Equipment Introduction:

- This model of liquid filling machine is suitable for the filling of beverages, liquor, edible oil, adhesive, daily chemicals, pharmaceuticals, pesticides, motor oil, and other substances.

- The machine adopts a self-priming pump and a novel filling device that determines the filling volume based on working time or motor speed. It is entirely made of stainless steel, with a simple structure and easy operation.

- The discharge nozzle can be detached, and the flexible tube can be extended for flexible filling, meeting the demand for unlimited filling capacity of 10ml and above.

Technical Parameters:

Operating Mode: Electric Self-Priming

Power Supply: 220V/380V 50Hz

Power: 0.4W-0.8KW

Filling Accuracy: ±2%

Filling Volume: 10ml to Unlimited

Working Capacity: 10-300 pcs/min

Machine Dimensions: 560×620×1020mm

Net Weight: 45KG

Automatic Quantitative Liquid Filling Machine

Principle Features:

- Suitable for filling toxic, corrosive, and volatile liquids such as pesticides, toluene, xylene, liquid fertilizer, veterinary medicine, disinfectant, oral liquid, alcoholic beverages, and other materials.

- Fast speed, high precision, with precise electromagnetic valve metering.

- Convenient filling volume adjustment: Adjust the filling time or replace the filling head through the keyboard for continuous and adjustable filling.

- Made of stainless steel and corrosion-resistant materials, with few wearing parts, easy cleaning, maintenance, and material replacement.

- Adjustable worktable height to accommodate containers of different sizes.

- Equipped with an automatic feeding device and material recovery interface to minimize waste.

Technical Parameters:

- Power Supply: AC220V 50HZ 400W

- Filling Speed: 800-3500 bottles/hour

- Filling Accuracy: ±1%

- Filling Range: 10-1000ml

- Machine Weight: 70kg

- Main Machine Dimensions: 500×400×1100mm

Pesticide/Animal Medicine Filling Machine

Introduction:

This four-head liquid filling machine is one of our company's flagship products. With mature technology, stable quality, easy operation, long lifespan, wide range of applicable materials, and a large adjustable filling range, it is highly cost-effective and favored by users.

Key Features:

- Constructed with high-quality stainless steel and components from well-known brands, it is corrosion-resistant, wear-resistant, and stable in performance.

- The filling process is controlled by a PLC microcomputer, ensuring easy operation, accurate measurement, and a precision of 5%.

- The filling range is extensive, adjustable between 200-5000ml.

- The unique up-and-down adjustment and submersion function of the filling outlet increase the filling space and prevent material overflow due to fast filling speed, accommodating various bottle shapes, including irregular ones.

- Four filling valves allow adjustment of the speed for each filling nozzle, ensuring accuracy.

- Users can choose between electric and pneumatic power according to their needs.

- Wide applicability, suitable for filling special products like pesticides (insecticides, disinfectants, herbicides, emulsions), fertilizers (foliar fertilizer, top dressing, water-soluble fertilizer), animal medicines (disinfectant water, oral liquids, feed additives), and chemical products (antifreeze, windshield washer fluid). It can also fill alcoholic beverages, mineral water, tea drinks, and other water-based beverages. The machine complies with GMP production requirements.

Technical Parameters:

- Filling Speed: 500-1500 bottles/hour

- Filling Accuracy: ±0.5%

- Filling Range: 200-5000ml

- Power Supply: 220V

- Power: 0.1kw

- Machine Weight: 80kg

- Machine Dimensions: 10007001350mm

Perfume/Lotion Filling Machine

Product Introduction:

The working principle of the perfume/lotion filling machine (self-draining type) involves opening the hand-pulled valve and connecting it to the air source. Place the bottle to be filled directly under the filling head and use the elastic material bottle tray to make the bottle stand upright, sealing it with the filling head. At this point, the cam opens the mechanical valve, closing the vacuum bottle valve and opening the suction material valve, creating a vacuum (negative pressure) in the vacuum generator. This forms a vacuum environment system (vacuum bottle-filling head-filling bottle-filling head silicone tube). The vacuum suction allows the material to fill the bottle. When the material in the bottle rises to the height of the outer jacket of the filling head, the vacuum suction through the outer jacket tube sucks the material in the bottle into the vacuum bottle, maintaining a constant height until the filled bottle is removed. The mechanical valve closes, the vacuum generator stops producing a vacuum, the material suction tube closes, the vacuum bottle valve opens, and the material in the vacuum bottle flows into the material bucket by gravity, completing one filling cycle. Based on similar foreign products, this machine has been redesigned and additional features have been added to simplify its use, operation, accuracy adjustment, equipment cleaning, maintenance, etc.

Performance Characteristics:

- Fully pneumatic control suitable for high foam and irregularly submitted product filling.

- The product design concept involves pressurizing the filling head to achieve a partial sealing environment, creating a local vacuum (negative pressure) and achieving filling through vacuum material suction.

Application:

Suitable for juice beverages, carbonated beverages, alcoholic beverages, mineral water, purified water, hair care products, skincare products, cosmetics, cleaning and washing products, oral liquids, and medicinal liquids.

Technical Parameters:

- Power: 80(w)

- Dimensions: 7506001300mm

- Number of Filling Heads: 4

- Filling Volume: 10-500ml

- Applicable Bottle Height: 50-300 (MM)

- Applicable Bottle Neck: 15-100 (MM)

- Production Capacity: 60 (bottles/minute)

- Filling Accuracy: ±1%

- Packaging Type: Bottle

- Working Principle: Negative pressure

- Applicable Objects: Oral liquids, medicinal liquids, liquid alcohol

- Applicable Industries: Daily chemical, medicine, chemical, others.

- Material Type: Liquid

- Automation Level: Semi-automatic

Horizontal Pneumatic Paste Filling Machine

Detailed Introduction:

- Suitable for quantitative filling of liquids, pastes, sauces, granules, etc., in industries such as chemicals, food, daily chemicals, medicine, pesticides, and lubricating oil.

- The cylinder, machine shell, and hopper of this model are made of stainless steel, and the piston is made of polytetrafluoroethylene. The pneumatic part adopts imported pneumatic components, meeting GMP requirements.

- Both the filling volume and speed are adjustable. It features a foot switch and automatic filling function, high precision, simple structure, and convenient operation.

Technical Parameters:

- Air Pressure: 0.4NPA

- Working Method: Pneumatic

- Filling Speed: ≤50 times/minute

- Filling Range: 5-100ml, 10-280ml, 20-500ml, 100-1000ml, 500-2000ml, 2000-5000ml

- Filling Accuracy: ±1%

- Hopper Capacity: 30L

- Weight: 50kg

- Dimensions: 1200mm×300mm×700mm

Fully Automatic Piston Type Paste Filling Machine

Equipment Introduction:

This series of concentrated sauce filling machine is a new generation fully automatic filling machine developed by our company with years of production experience and the introduction and absorption of advanced world-class technology. It adopts piston quantification, integrates mechanics, electricity, and pneumatics, and uses world-renowned brands for electrical and pneumatic components. Controlled by PLC, it is designed with reasonability, compact structure, beautiful appearance, and features stable and reliable performance, high filling accuracy, strong adaptability, simple operation, and easy maintenance. It is widely used in the filling of various semi-fluids, pastes, viscous materials, sauces, and materials containing particles, such as fruit pulp beverages, honey, syrup, jam, peanut butter, sesame paste, tomato sauce, chili sauce, and various pasty substances.

Performance Features:

- Adopts world-renowned electrical and pneumatic components, with low failure rate, stable and reliable performance, and long service life.

- All parts in contact with materials are made of stainless steel, easy to disassemble, easy to clean, and compliant with food hygiene requirements.

- Simple adjustment of filling volume and speed, equipped with a function to prevent filling when there is no bottle, automatic control of material addition based on liquid level, and beautiful appearance.

- Quick adjustment and replacement of bottles of different shapes and specifications without changing parts, demonstrating strong applicability.

- Filling nozzles are equipped with anti-drip devices to ensure no drawing or dripping during filling.

Technical Parameters:

- Filling Speed: 10-30 bottles/min

- Filling Accuracy: ≤±1%

- Power Supply: 220/110V 50/60Hz

- Air Pressure: 0.5-0.7MPa

- Current: 3A

Horizontal Pneumatic Paste Filling Machine

Detailed Introduction:

- Suitable for quantitative filling of liquids, pastes, sauces, granules, etc., in industries such as chemicals, food, daily chemicals, medicine, pesticides, and lubricating oil.

- The cylinder, machine shell, and hopper of this filling machine are made of stainless steel, and the piston is made of polytetrafluoroethylene. The pneumatic part adopts imported pneumatic components, meeting GMP requirements.

- Both the filling volume and speed are adjustable, with a foot switch and automatic filling function, high precision, simple structure, and convenient operation.

Technical Parameters:

- Number of Filling Heads: 2

- Air Pressure: 0.4NPA

- Working Method: Pneumatic

- Filling Speed: ≤60 times/min

- Filling Range: 5-100ml, 10-280ml, 20-500ml, 100-1000ml

- Filling Accuracy: ±1%

- Hopper Capacity: 30L

Stirring Type Paste Filling Machine

Detailed Introduction:

- Suitable for quantitative filling of liquids and pastes in industries such as chemicals, food, daily chemicals, medicine, pesticides, and lubricating oil.

- The cylinder, machine shell, and hopper of this filling machine are made of stainless steel, and the piston is made of polytetrafluoroethylene. The pneumatic part adopts imported pneumatic components, meeting GMP requirements.

- Both the filling volume and speed are adjustable, with a foot switch and automatic filling function, high precision, simple structure, and convenient operation.

Technical Parameters:

- Air Pressure: 0.4NPA

- Working Method: Pneumatic

- Filling Speed: ≤50 times/min

- Filling Range: 5-100ml, 10-280ml, 20-500ml, 100-1000ml

- Filling Accuracy: ±1%

- Hopper Capacity: 30L

- Weight: 50Kg

- Dimensions: 930mm×420mm×750mm

Semi-Automatic Chili Sauce Filling Machine

Introduction:

This machine is specifically designed for the quantitative filling and packaging of items such as hot pot base, viscous sauces, and chunky meat sauces. It is suitable for filling various viscous substances containing solid materials such as chili, peanuts, meat chunks, condiments, etc., and the separation of sauce and oil in hot pot bases. It is applicable to filling various containers and suitable for butter hot pot base, red oil hot pot base, chili sauce, honey juice, jam, and more. The machine can automatically complete the processes of measurement and filling. The entire machine adopts a stainless steel structure, and all parts in contact with the material are made of stainless steel to ensure compliance with international hygiene standards. The filling volume can be adjusted within the specified range with small measurement errors. The machine is powered by compressed air and operates in various environments.

Product Features:

- The discharging valve control system uses unique patented technology, allowing for the filling of semi-fluids and viscous substances containing large solid particles, and mixtures of sauce with oil, water, and materials that are separated.

- The machine can be operated by the personnel using a foot pedal control switch or set up with a photoelectric induction switch. It automatically completes the processes of measurement and discharging in one action.

- Different equipment models can be configured according to the customer's different materials, suitable for various materials, including those with solid particles and viscous substances.

- The operator manually holds the container, controls the switch for discharging, making it convenient to use and operation simple.

Technical Specifications:

- Packaging Materials: Hot pot base, viscous sauces, etc., such as hot pot base, chili sauce, peanut butter, fish roe sauce, ginger sauce, honey, etc.

- Measurement Method: Plunger pump volume measurement

- Measurement Range: 100~500g

- Filling Speed: 10~30 times/min

- Filling Accuracy: ±1.5%

- Total Power: 0.75KW

- Power Supply Voltage: 220V/50Hz

Stirring Type Sauce Electric Filling Machine

Introduction:

This sauce filling machine uses a photoelectric self-control system and a unique piston filling form, allowing for both continuous and free filling.

- The machine adopts a horizontal stirring structure to ensure thorough mixing of sauce and oil, greatly improving filling performance and measurement accuracy.

- This machine is designed and produced for the sauce filling needs of the food industry, especially suitable for viscous sauces with particles and high concentration, such as chili sauce, bean paste, peanut butter, sesame paste, jam, butter hot pot base, red oil hot pot base, etc.

Technical Parameters:

- Working Speed: 30-40 times/min

- Capacity Measurement: 100-1000ml, 500-1500ml

- Quantitative Error: ±2%

- Power Supply Voltage: 380V 2.1Kw

- Dimensions: 1400×600×1200mm

- Machine Weight: 250kg

Viscous Liquid Quantitative Filling Machine

Introduction:

- This model filling machine is suitable for the filling, sub-packaging, and metering of various oils, fats, and oil materials such as lubricating oil, edible oil, barrel wine, chemical products, and spices.

- The machine is mainly composed of a magnetic cylinder, an oil cylinder, and electrical control components. It has the advantages of a simple overall structure, a small footprint, and easy operation.

- It adopts a quantitative cup structure, where the oil cylinder piston is driven by the cylinder to move repeatedly, accurately filling the oil into the bottle. It has high accuracy, fast filling speed, dual-speed filling (fast initially and slower later), ensuring more accurate measurement.

Technical Parameters:

- Production Capacity: 100-300 times/hour/head

- Filling Volume: 1-5 liters

- Working Voltage: 220/380V

- Air Pressure: 0.5-0.7Mpa

- Dimensions: 600×598×1300mm

- Weight: 70Kg

Fully Automatic Oil Filling Production Line

Introduction: This fully automatic oil filling machine is mainly used for the quantitative filling of various oil liquids, such as edible oil, lubricating oil, peanut oil, soybean oil, corn oil, engine oil, antifreeze, etc.

- Digital display screen for direct setting of filling volume.

- PLC program control, frequency converter speed regulation for linear filling.

- High-precision volumetric flowmeter for accurate and reliable quantification.

- Mechanical sealing with vacuum return suction for double-leak prevention.

- Dual-flow speed efficient filling with initial fast and later slow speed.

Technical Parameters:

- Number of Filling Heads: 2 heads - 10 heads

- Production Capacity: 200-400 barrels/hour

- Capacity Range: Stepless adjustment 1-6 liters

- Filling Accuracy: ≤±0.5%FS

- Air Pressure: 0.5-0.7MPa

- Working Voltage: 220V 50Hz

Semi-Automatic Oil Filling Production Line

Product Introduction:

- This semi-automatic oil filling production line is designed for the quantitative filling of viscous liquids such as edible oil, beverages, lubricating oil, pharmaceutical liquids, and chemical products.

- The machine adopts a piston-type automatic filling method, suitable for various bottle types. It operates on the principle of piston quantification, offering adjustable continuous quantification, accurate measurement, and strong adaptability.

- Pneumatic-driven with drip-proof nozzle.

- Semi-automatic control.

- Photoelectric sensing automatic capping machine.

- Mechanical anti-drip feature.

Configuration: Double-head semi-automatic filling machine + 2-meter conveyor line + automatic sensing capping machine.

Features:

- Low combined machine price.

- Reduces labor intensity.

- Enhances work efficiency.

Technical Parameters:

- Number of Filling Heads: 2 heads

- Production Capacity: 100-250 bottles/hour per head

- Capacity Range: 0.5-5 liters

- Filling Accuracy: ≤±0.5%FS

- Air Pressure: 0.5-0.7 MPa

- Power Consumption: <1000W

Semi-Automatic Hot Pot Base Filling Machine

This machine is specially designed for the quantitative filling and packaging of hot pot bases, viscous sauces, and chunky meat sauces. It is suitable for filling various viscous substances containing solid materials such as chili, peanuts, meat chunks, condiments, etc. The machine is ideal for filling hot pot bases where oil and ingredients need to be separated. It is applicable to various containers and can be used for filling ingredients like beef hot pot base, spicy oil hot pot base, chili sauce, honey juice, fruit jam, and more. The machine can automatically complete the processes of measurement and filling.

Key Features:

- The discharge valve control system uses a unique patented technology, allowing it to fill semi-fluid and viscous materials with large solid particles, as well as mixed sauces with separated oil, water, and ingredients.

- It can be operated by personnel using a foot pedal control switch or can be set with a photoelectric sensing switch to automatically complete the processes of measurement and discharge in one step.

- Different equipment models can be configured according to customer needs to accommodate various materials, including those with solid particles and viscous substances.

- Manual handling of containers with control switch discharge. Easy to use and operationally simple.

Technical Specifications:

- Packaging Materials: Hot pot base, viscous sauce, etc., such as beef hot pot base, chili sauce, honey, juice, etc.

- Measurement Method: Piston pump volumetric measurement

- Measurement Range: 100–500g

- Filling Speed: 10–30 times/min

- Filling Accuracy: ±1%

- Total Power: 0.75KW

- Power Supply Voltage: 220V/50Hz

TAG: Beverage Filling Machine Drinks Filling Machine Filling Machine

Core Selling Points of Glass Bottle CSD Filling & Capping Line

Customizable beverage filling system

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

The Convenience Brought by Beverage Filling Machines to the Beverage Industry

Essential Preparations for Beverage Production Line Installation

Essential Beverage Production Terms for Industry Professionals

Beverage Packaging: Which Is Better, PET Bottles or Glass Bottles?

3 Filling methods and characteristics of beverage filling machine

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine