Key Components of Filling Equipment

As the demand for precision increases, filling equipment becomes more automated and technologically advanced. To help you better understand filling equipment, let's discuss its key components

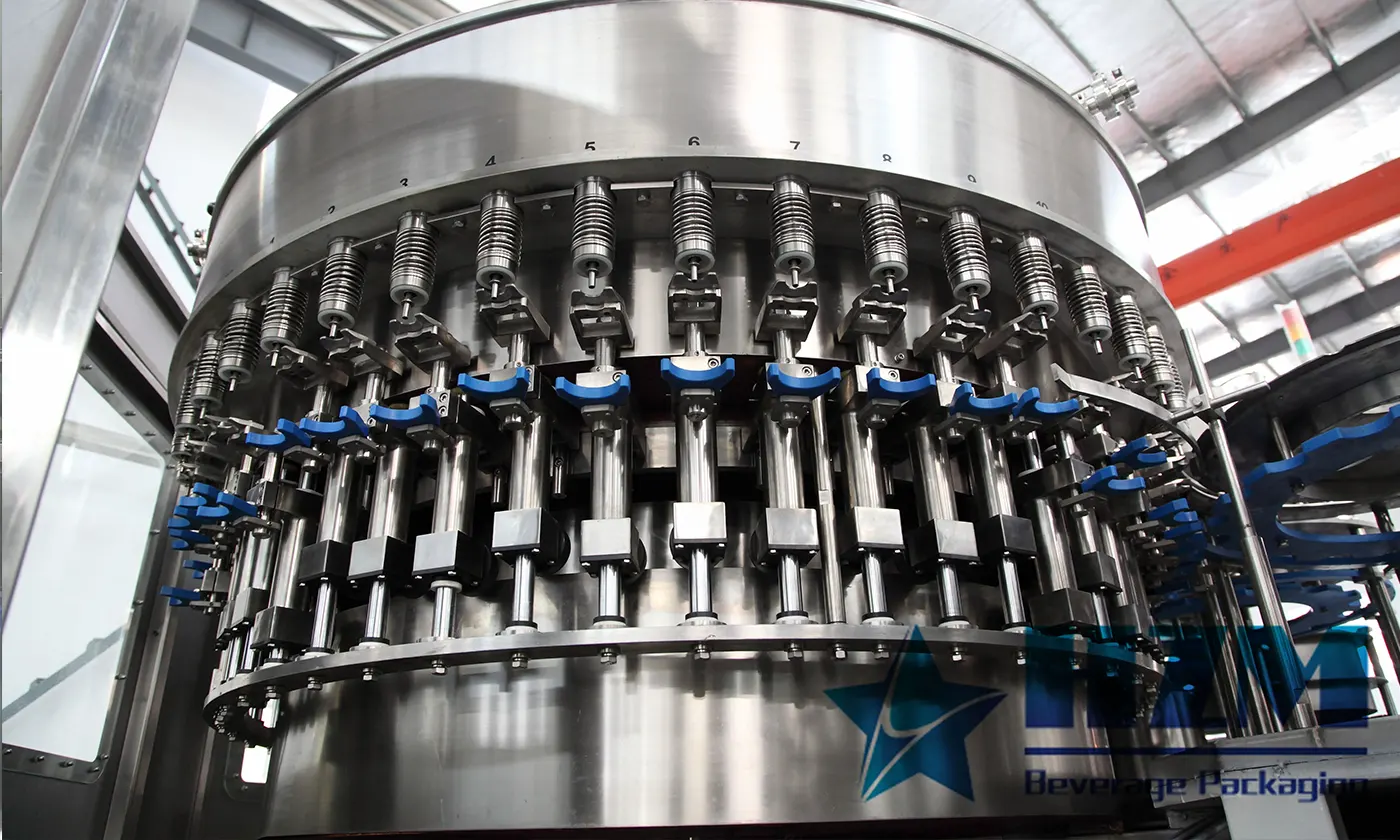

Filling Mechanism

This primarily consists of finished water pipes, water storage tanks, lifting filling valves, and positioning assemblies. Once the bottle is in position, the filling machine moves up and down under the action of cylinders, controlled by the bottle neck limit to open and close the valve. Product water is injected into the bottle from the water storage tank through pipelines, ensuring filling accuracy, adjustable liquid level, and sealing integrity.

Bottle Washing Mechanism

Comprising a frame, stainless steel frame, inlet pipes, bottle clamps, guide rails, lower water trays, upper water trays, and organic glass covers. After bottle positioning, it is clamped at the neck and flipped 180 degrees for inverted rinsing. Once rinsed, it is rotated back 180 degrees onto the conveyor chain. This ensures effective internal and external bottle rinsing while preventing splashing of rinsing liquid, with good maintainability and reliability.

Rotating Mechanism

Utilizes sealing mechanisms with imported high-energy magnets, including flat and cap-on devices. It boasts low wastage rates, adjustable torque, smooth and reliable operation, and high sealing qualification rates.

TAG: Automatic Filling Machine Bottled Water Filling Machines Water Filling Machines

0.5L Plastic PET 32000 BPH Bottled Water Filling Machines

Working Process of the 3-in-1 Isobaric Mono-block Filling Machine

Comprehensive Analysis of Bottled Water Production Line

Bottled Purified Water Production Line Equipment: Safeguarding from Source to Bottle

Streamlining Bottled Water Production: A Comprehensive Overview

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine