What equipment is needed to create a small to medium-sized carbonated beverage production line?

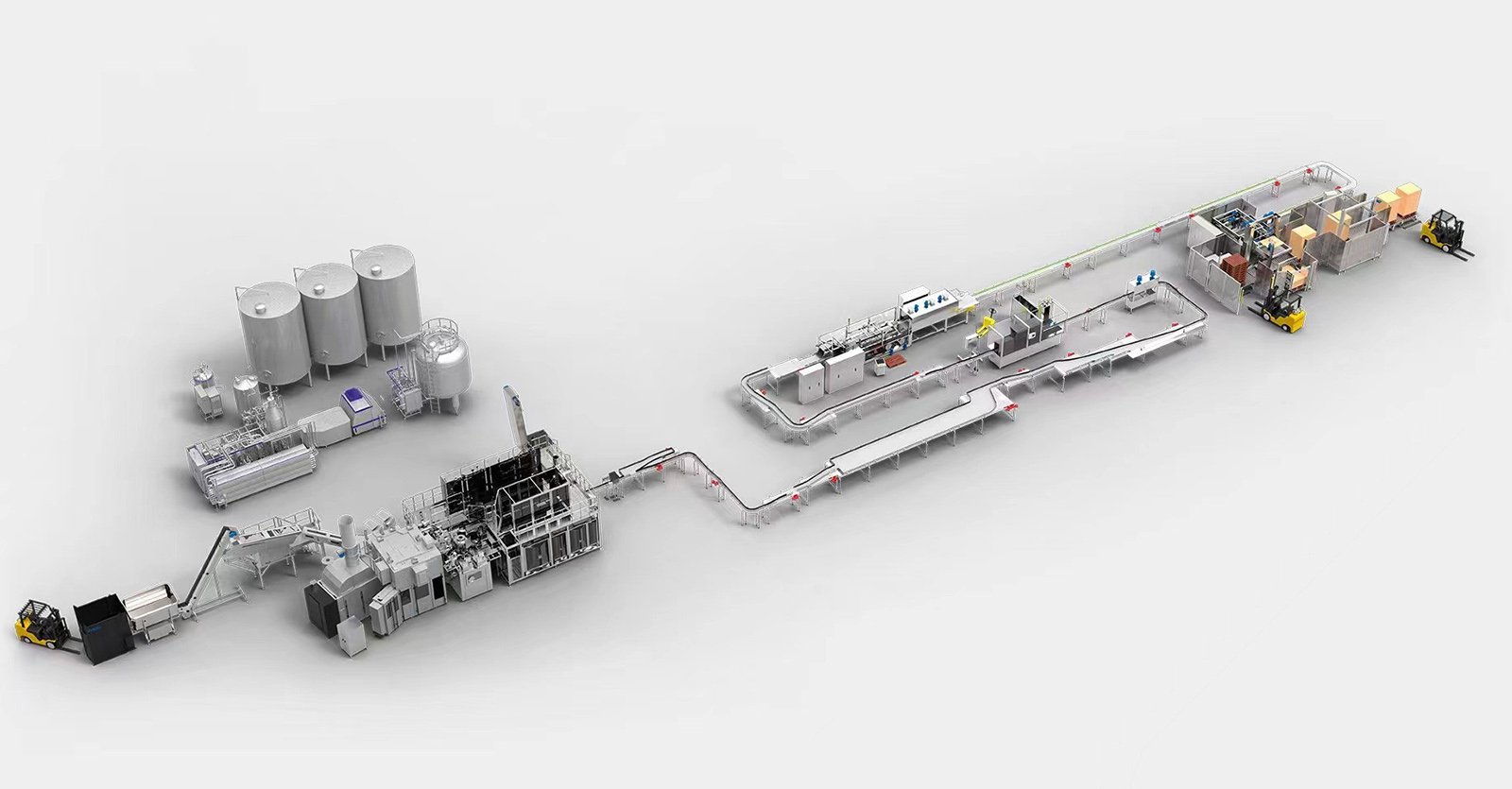

Carbonated beverages are fast-moving consumer goods, and producing carbonated beverages can be a profitable business. If you need to establish a small to medium-sized carbonated beverage production line, the following equipment is required:

- Water treatment equipment : reverse osmosis equipment for filtering the water used in carbonated beverages.

- Filling machine : For a daily production demand of 1000 units, a rotary filling line with a capacity of 1000-1500 bottles/hour is sufficient if overtime production is possible.

- Equipment material and key components : In order to be durable, the part of the equipment through which liquid flows must be made of 304 or 316 stainless steel, and other components such as pipes, valves, and pumps should be made of better quality brands to reduce the failure rate.

- Bottle blowing machine : The first step in the production line for blowing carbonated beverage bottles. The quality of the equipment directly affects the subsequent operation of the equipment. Once a malfunction occurs, the entire production line will stop running.

- Labeling machine, packaging machine : Labeling, packaging, and boxing the produced carbonated beverage bottles.

- Auxiliary equipment such as bottle washing machine : bottle sorting machine, cap sorting machine, inspection machine, soda sugar mixing machine, and oil-free air compressor.

These auxiliary devices are used for cleaning and testing bottles, checking the quality of finished and semi-finished products, and producing carbonated beverages. They are all equipment that assists in the operation of the filling production line.

If you do not have a factory building, the following things are also required:

- Preparation of factory rental fees.

- The factory building should be at least 4 meters high and 700 square meters or more (for one production line).

- Factory renovation, personnel disinfection facilities, clean workshop, laboratory, etc.

For example, if you want to produce 2000 bottles of beverages or water per hour, a minimum of 800 square meters of factory space is required. If that's not possible, at least try to locate the factory near a water source.

Therefore, to start a beverage factory that can produce stable quality and maintain its survival, you need to prepare the above equipment and conditions.

It should be noted that once you start, there's no turning back. Investors in small beverage companies often only focus on equipment investment costs, ignoring supporting facilities, start-up costs, QS declaration, customized molds, employee work injury insurance, packaging design, plate-making, recruitment, training, trial production, and other subsequent costs and time costs. It's important to develop two or more plans and emergency measures, and implement them cautiously.

HZM is a professional beverage filling machine manufacturer specializing in food and beverage machinery and pure water treatment equipment. It adheres to the business philosophy of market orientation, technology as the forerunner, quality is life, and service first, and has established a sound quality assurance system. Currently, HZM's main products include beverage filling production lines, liquid bottle, barrel, and can filling machinery and production lines for fruit juice, tea drinks, and alcoholic beverages, as well as downstream packaging systems and pure water treatment equipment. We warmly welcome new and old customers to visit and purchase our products.

TAG: Beverage Filling Machine Carbonated Beverage Filling Machine Filling Machine

Which Is a Good Beverage Filling Production Line? Key Selection Criteria & Recommendations

Core Selling Points of Glass Bottle CSD Filling & Capping Line

Customizable beverage filling system

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

The Convenience Brought by Beverage Filling Machines to the Beverage Industry

Essential Preparations for Beverage Production Line Installation

Essential Beverage Production Terms for Industry Professionals

Beverage Packaging: Which Is Better, PET Bottles or Glass Bottles?

-

![Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink]()

Beverage Packaging Machine for Juice, Soft Drinks, Carbonated Drinks, and Energy Drink

-

![Glass Bottle CSD & Water Drinks Filling Machine]()

Glass Bottle CSD & Water Drinks Filling Machine

-

![Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer]()

Automatic 5 Gallon Water Filling Line | 3-5 Gallon Bottled Water Production Line Manufacturer

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]()

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

-

![PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine]()

PET Bottle Edible Oil Bottling Line | Automatic Rotary Type Edible Oil Filling Machine